Arm Bar

Arm Bar

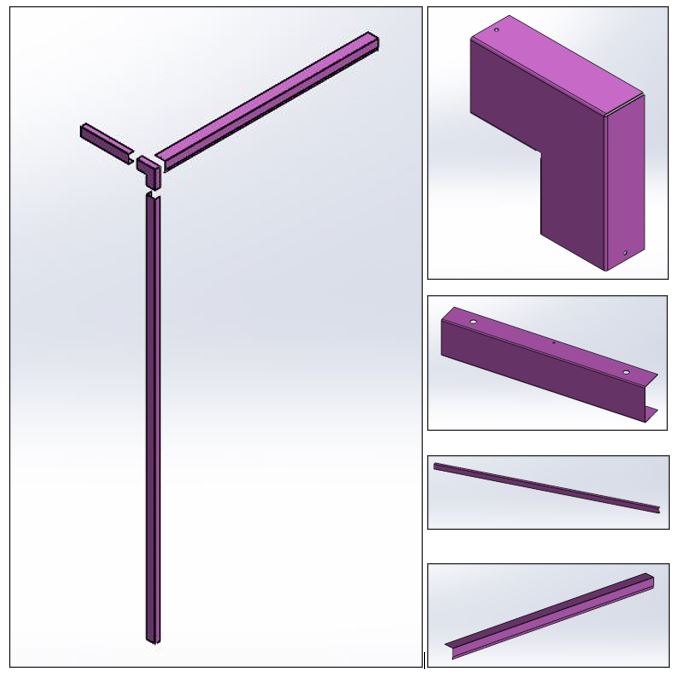

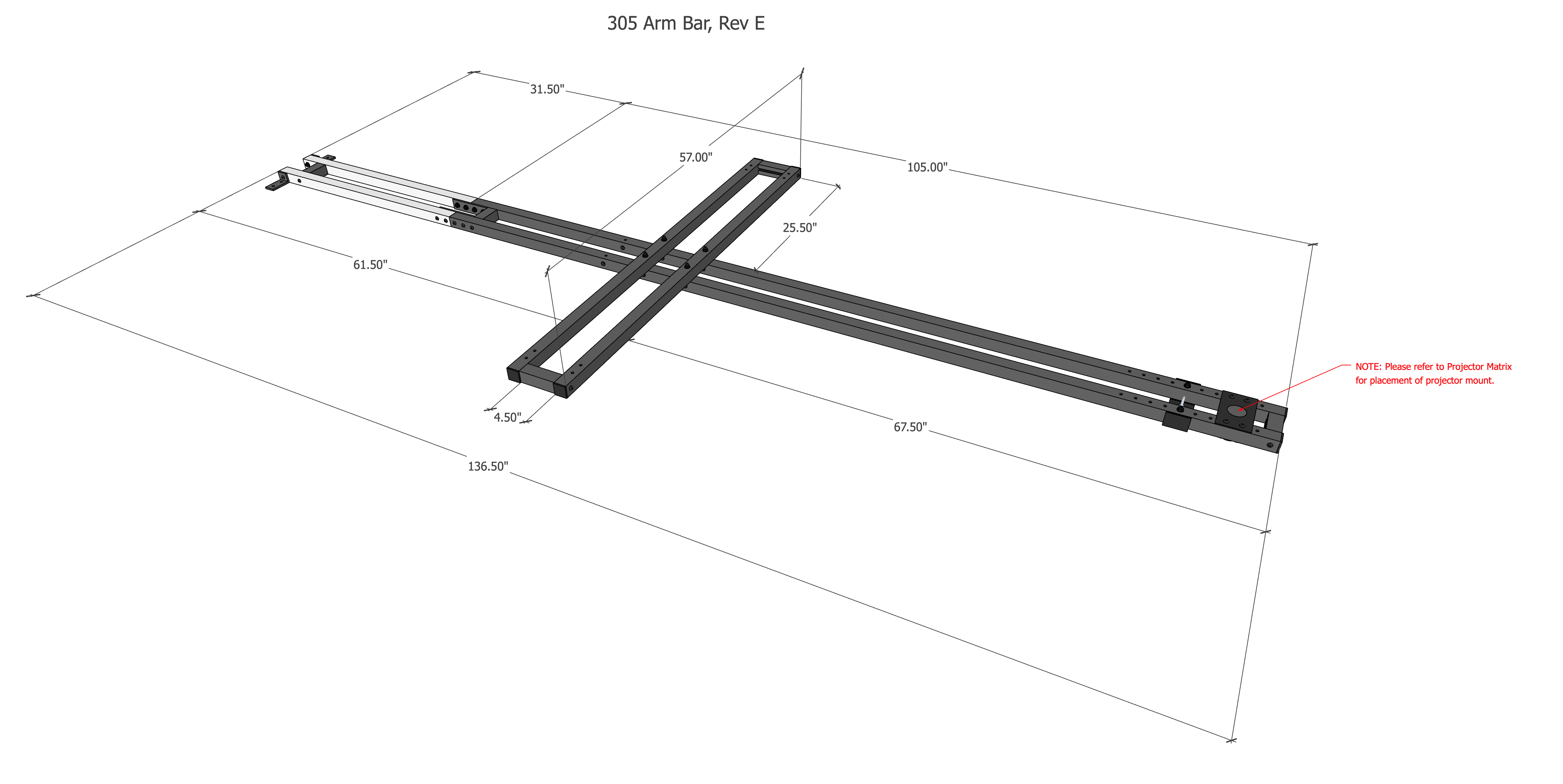

Arm Bar Illustration

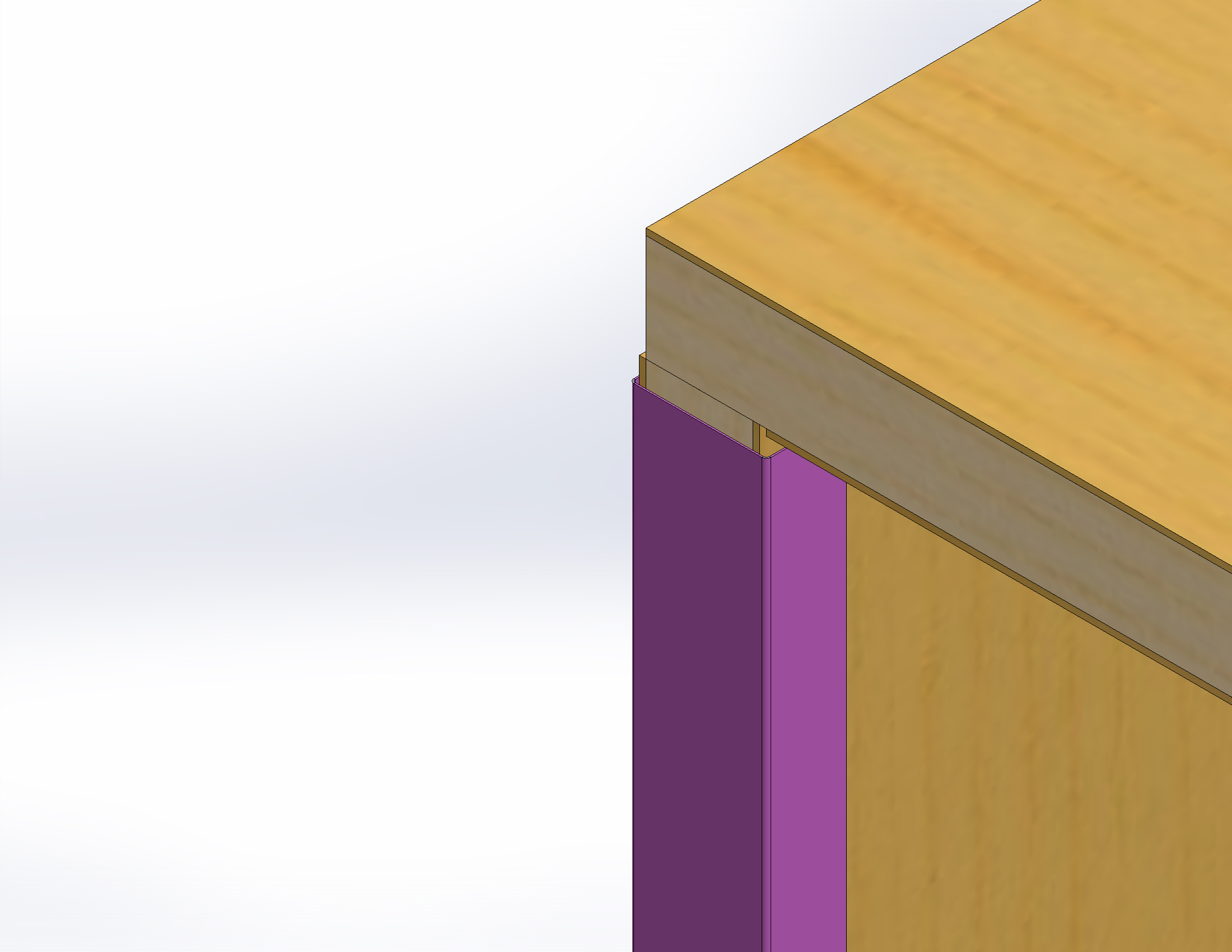

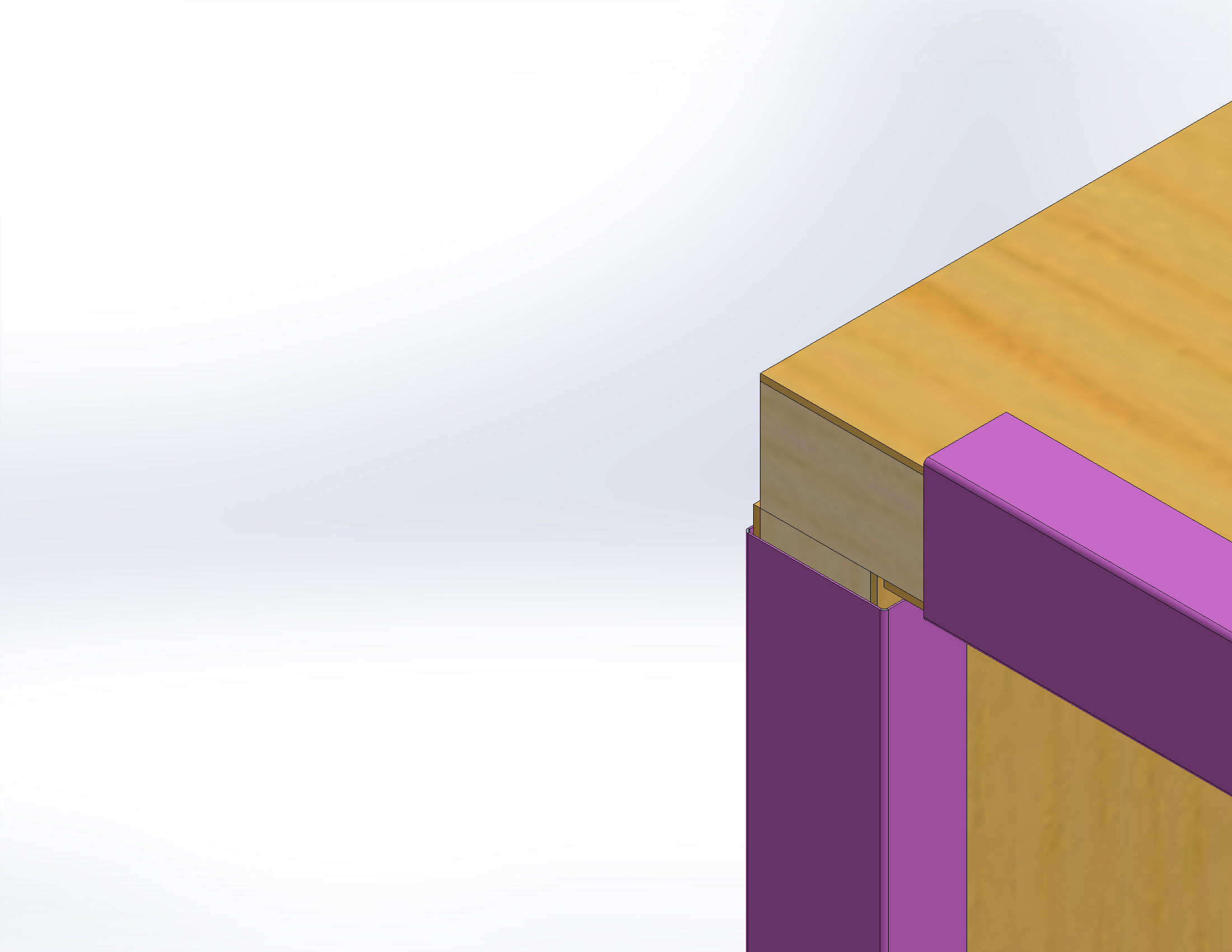

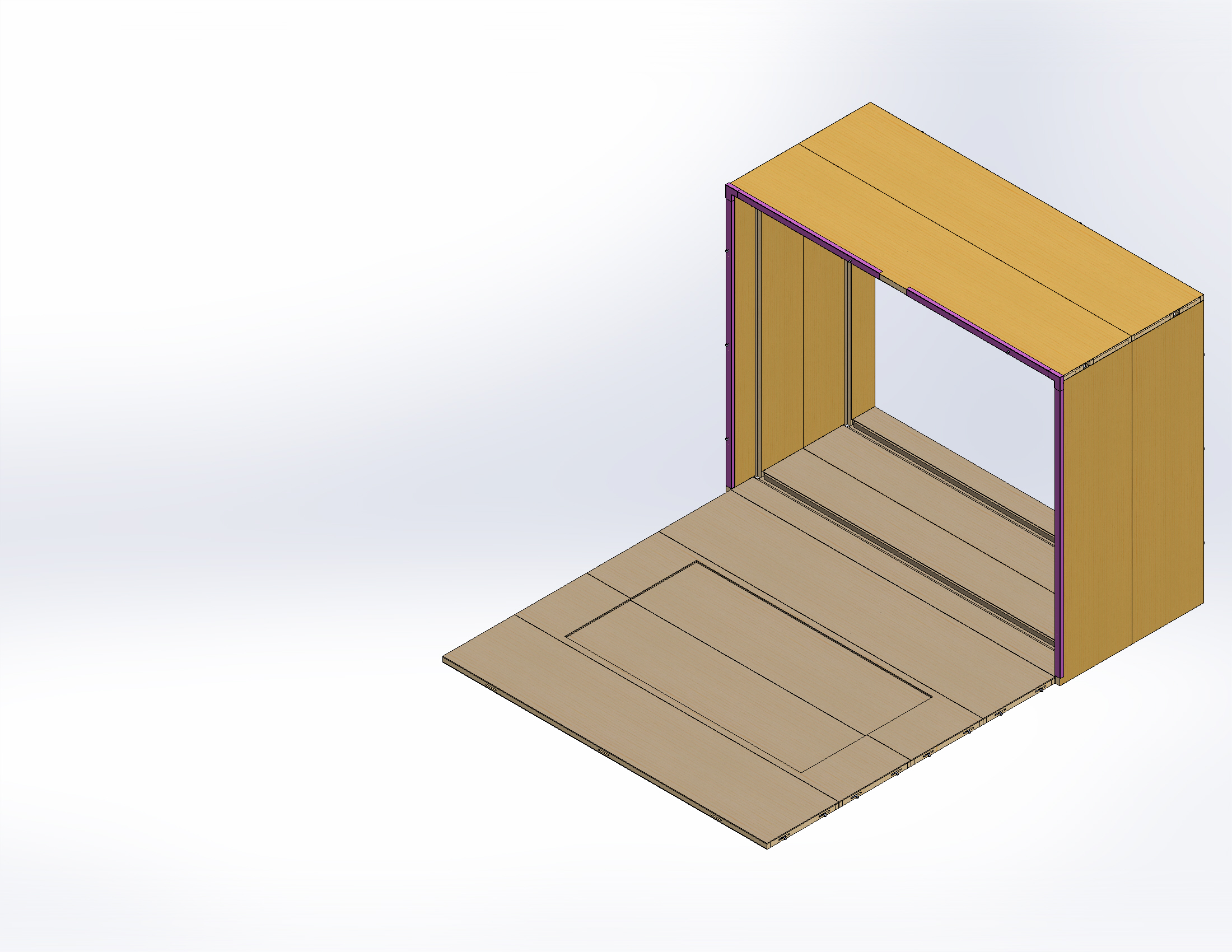

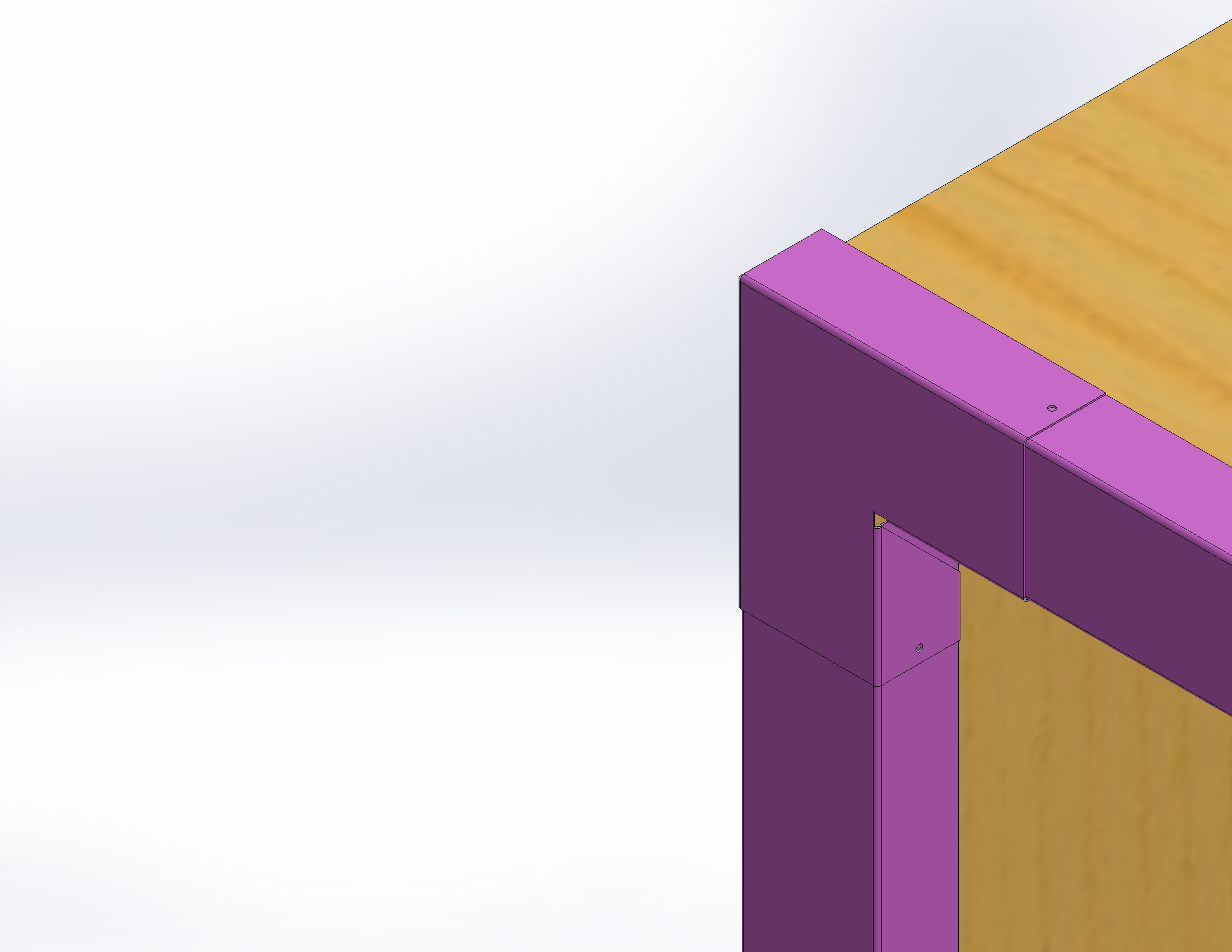

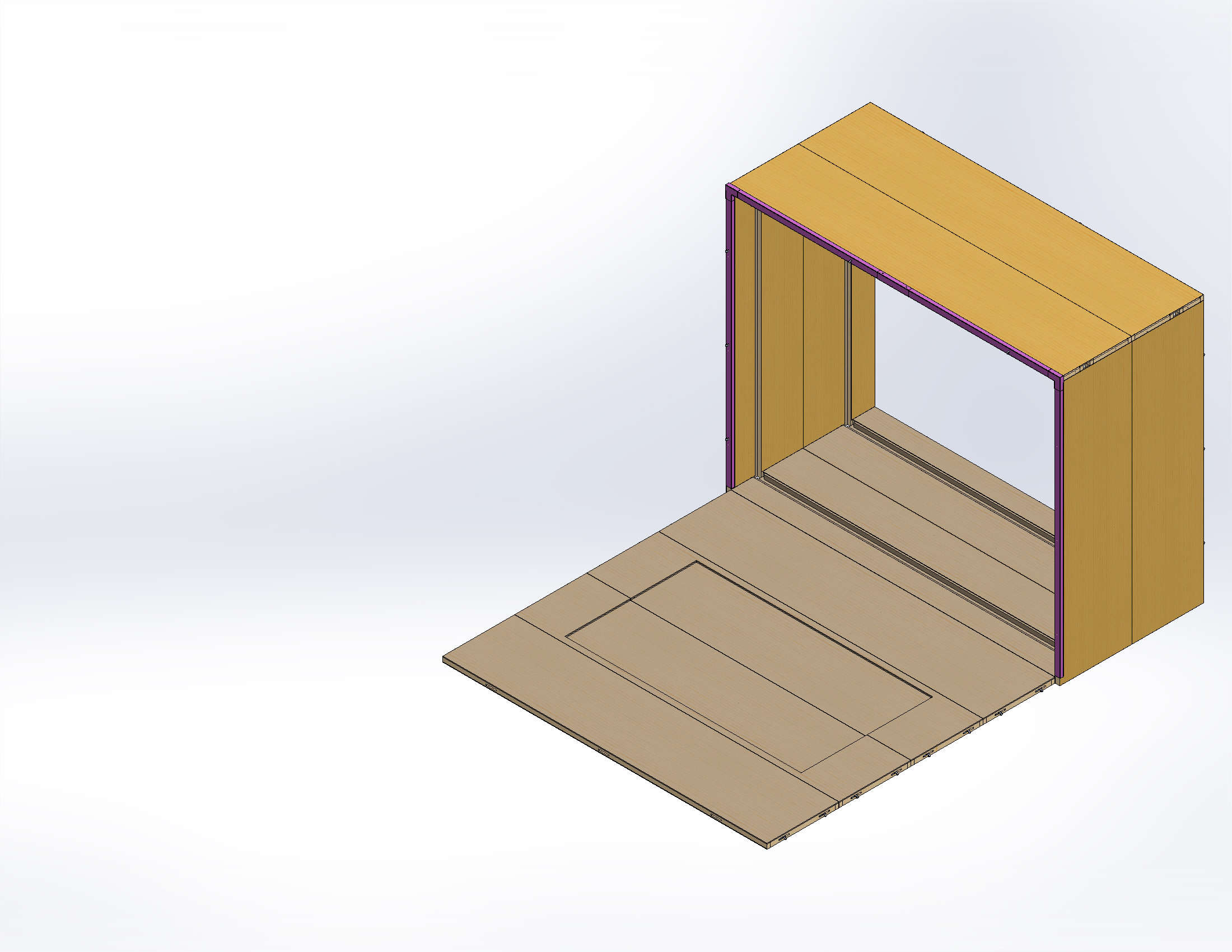

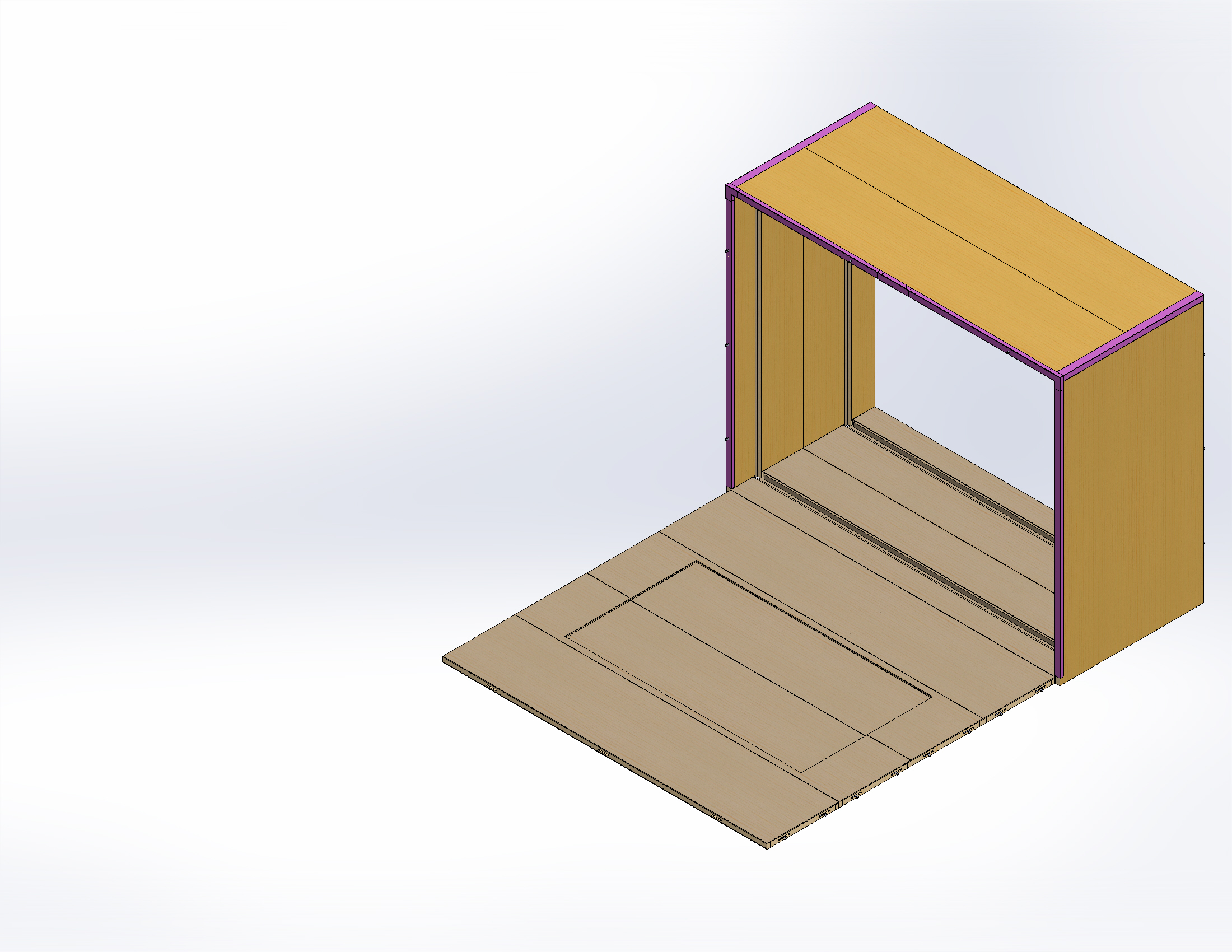

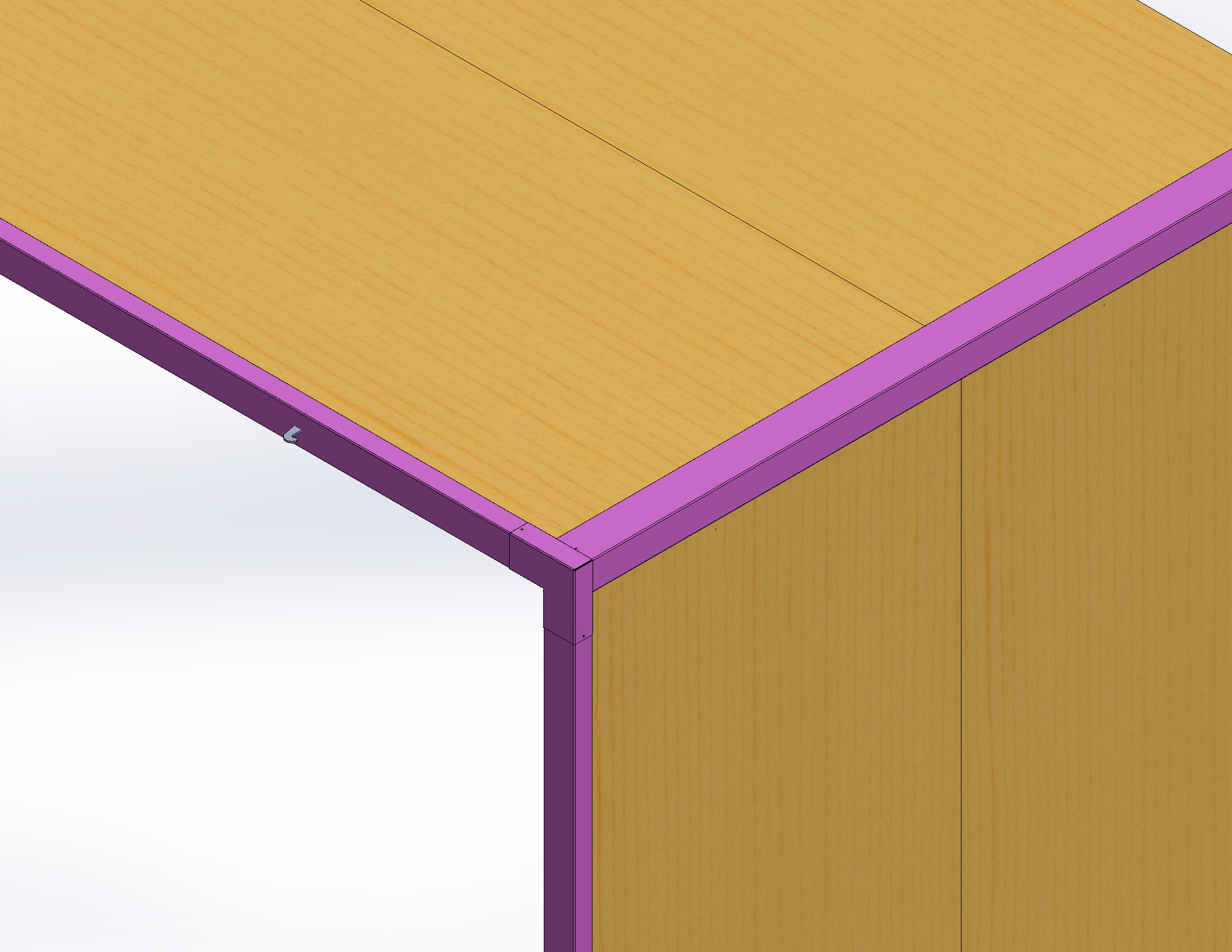

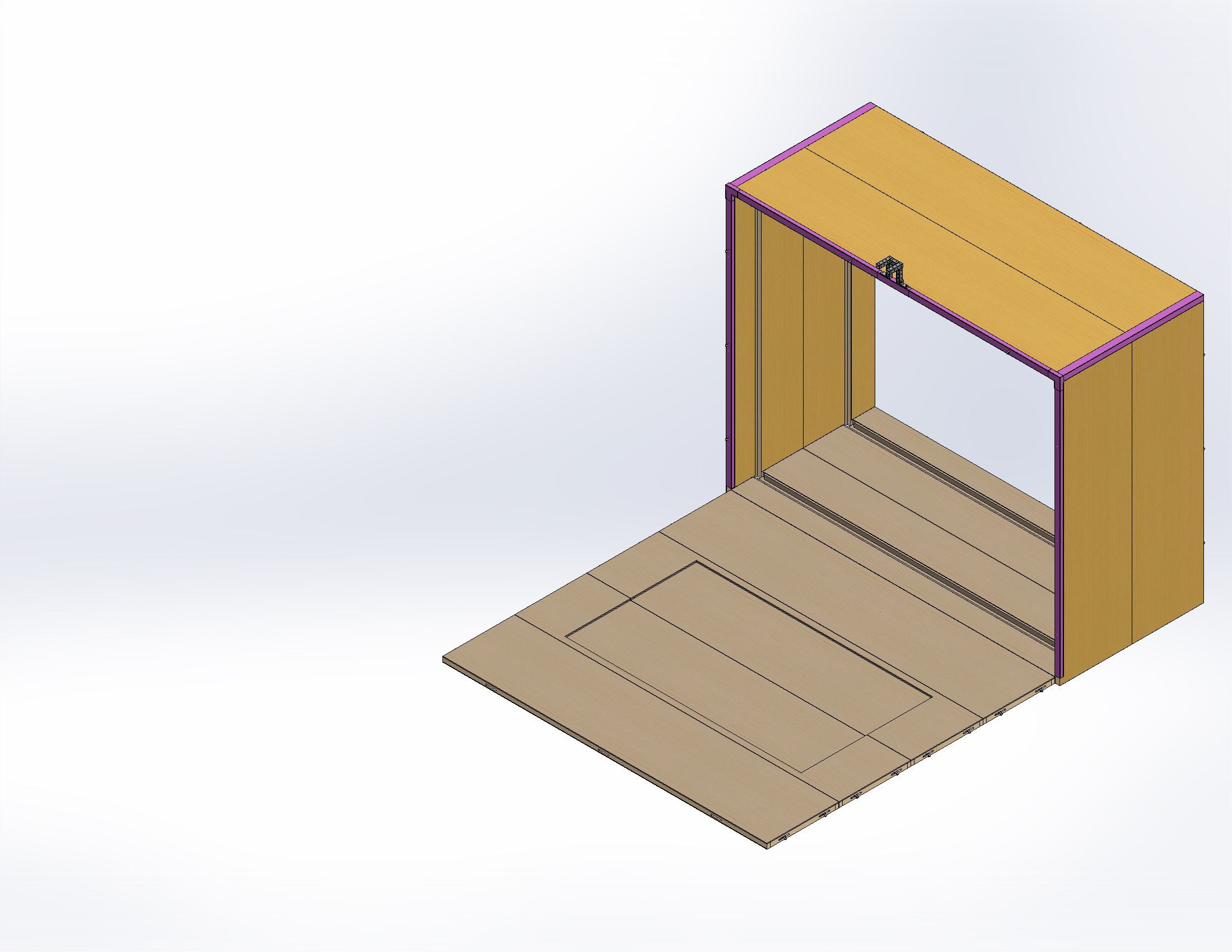

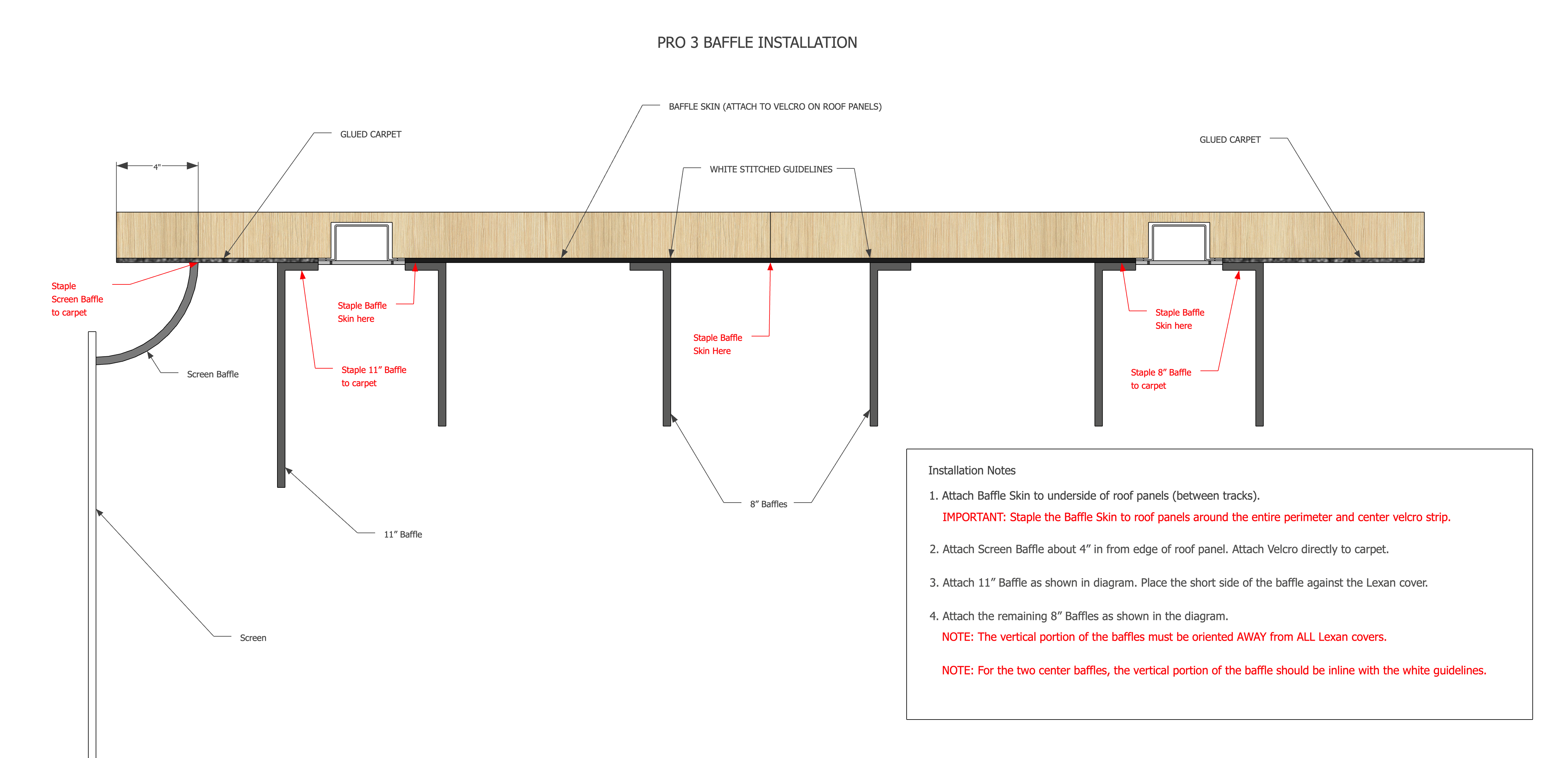

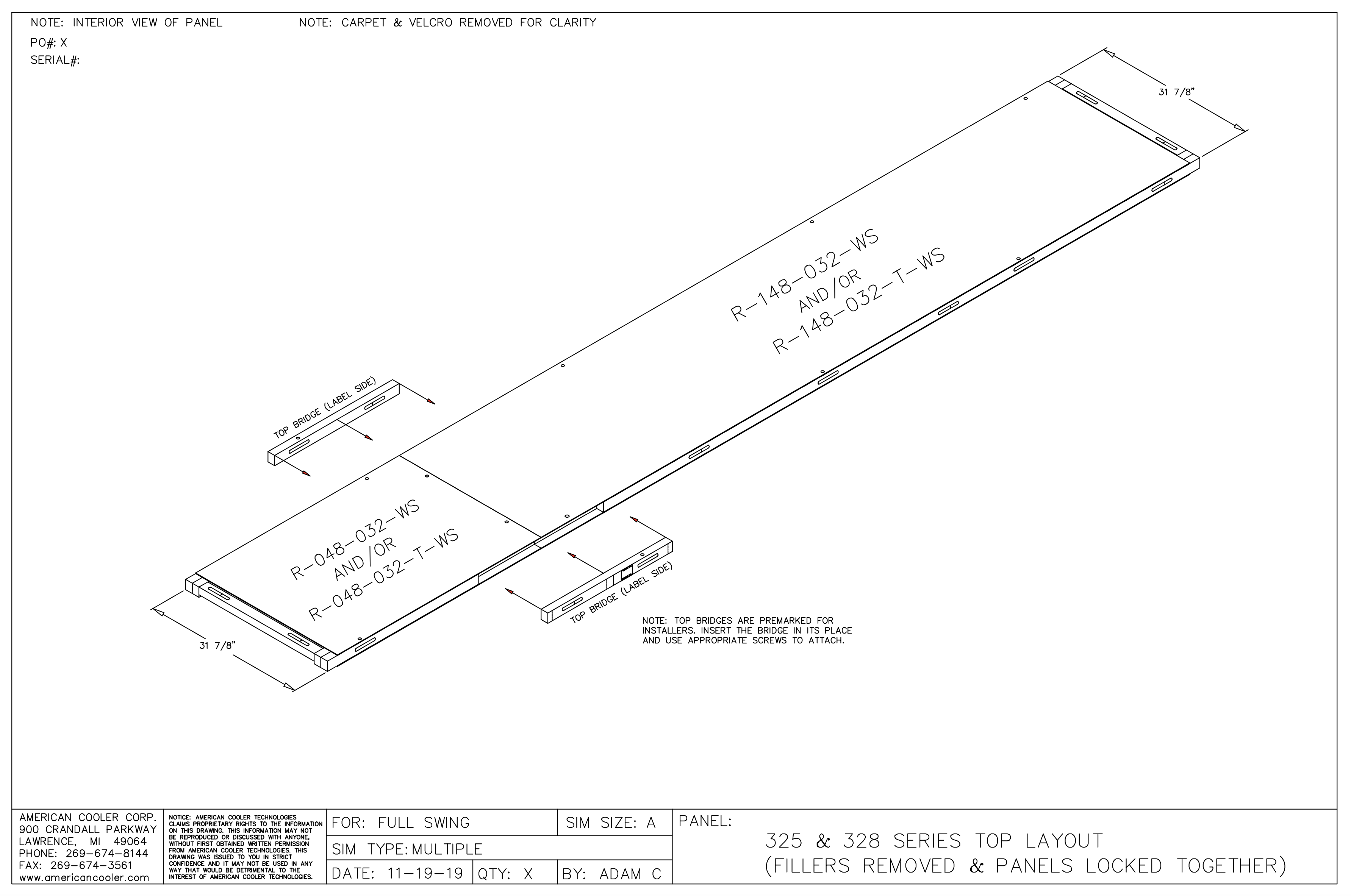

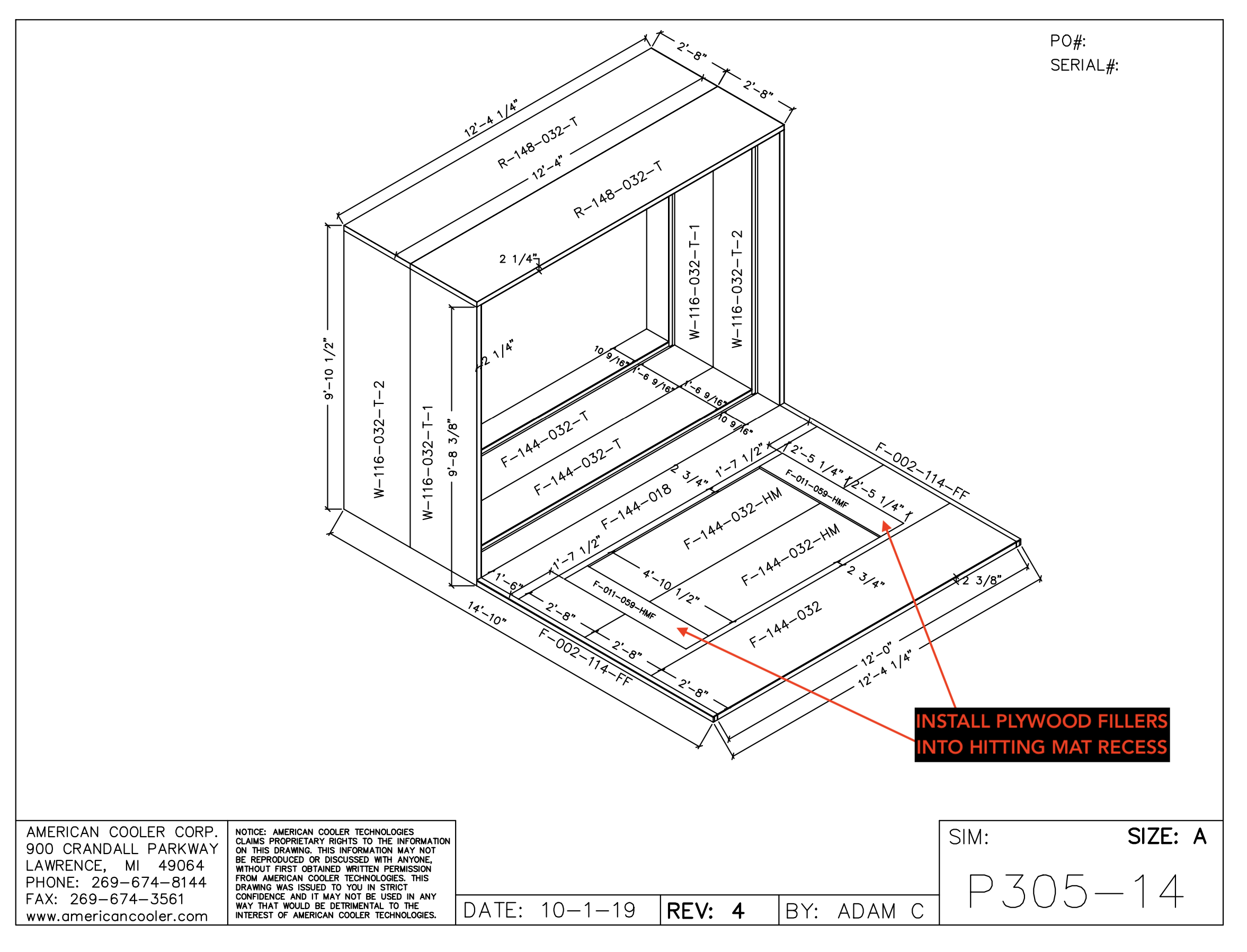

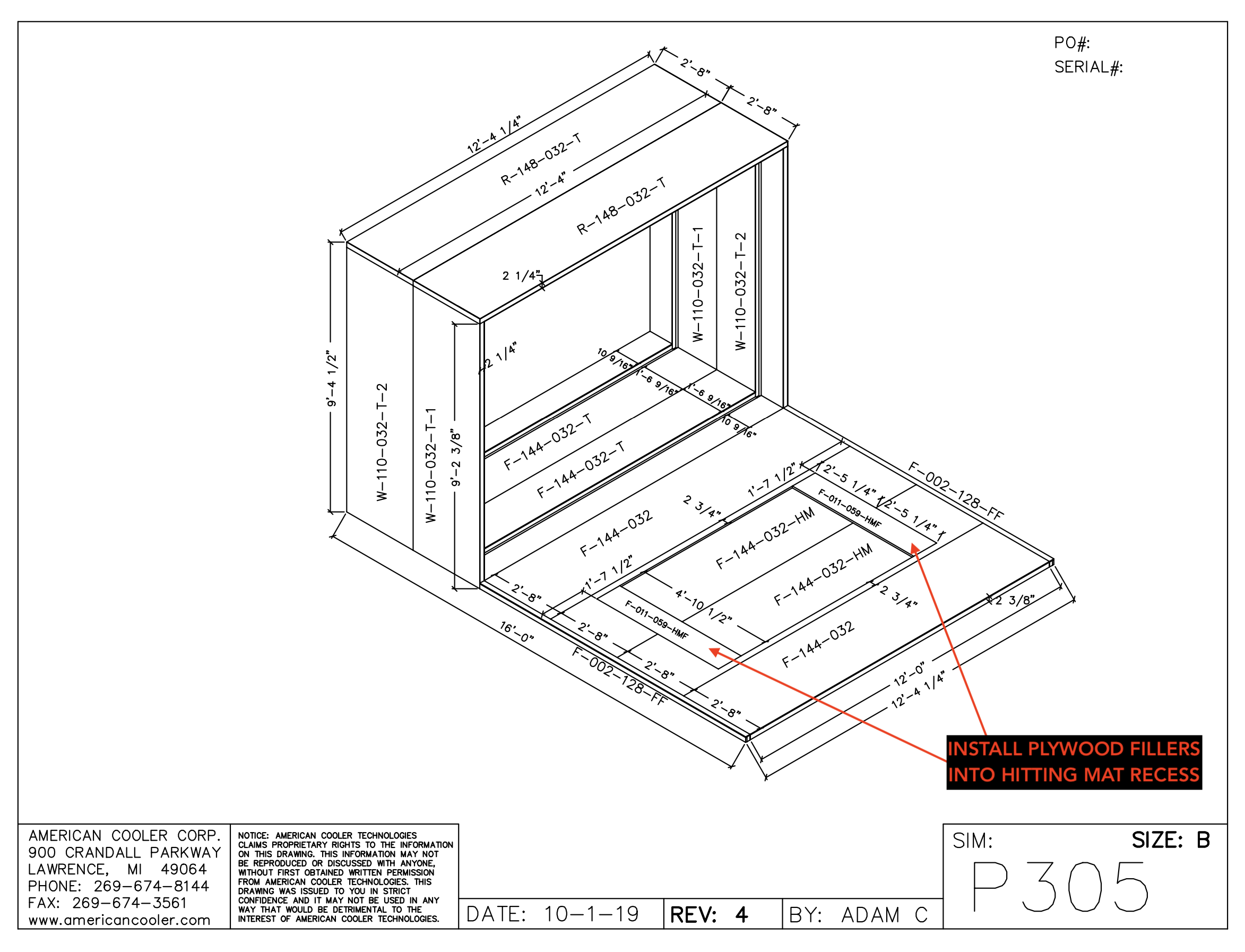

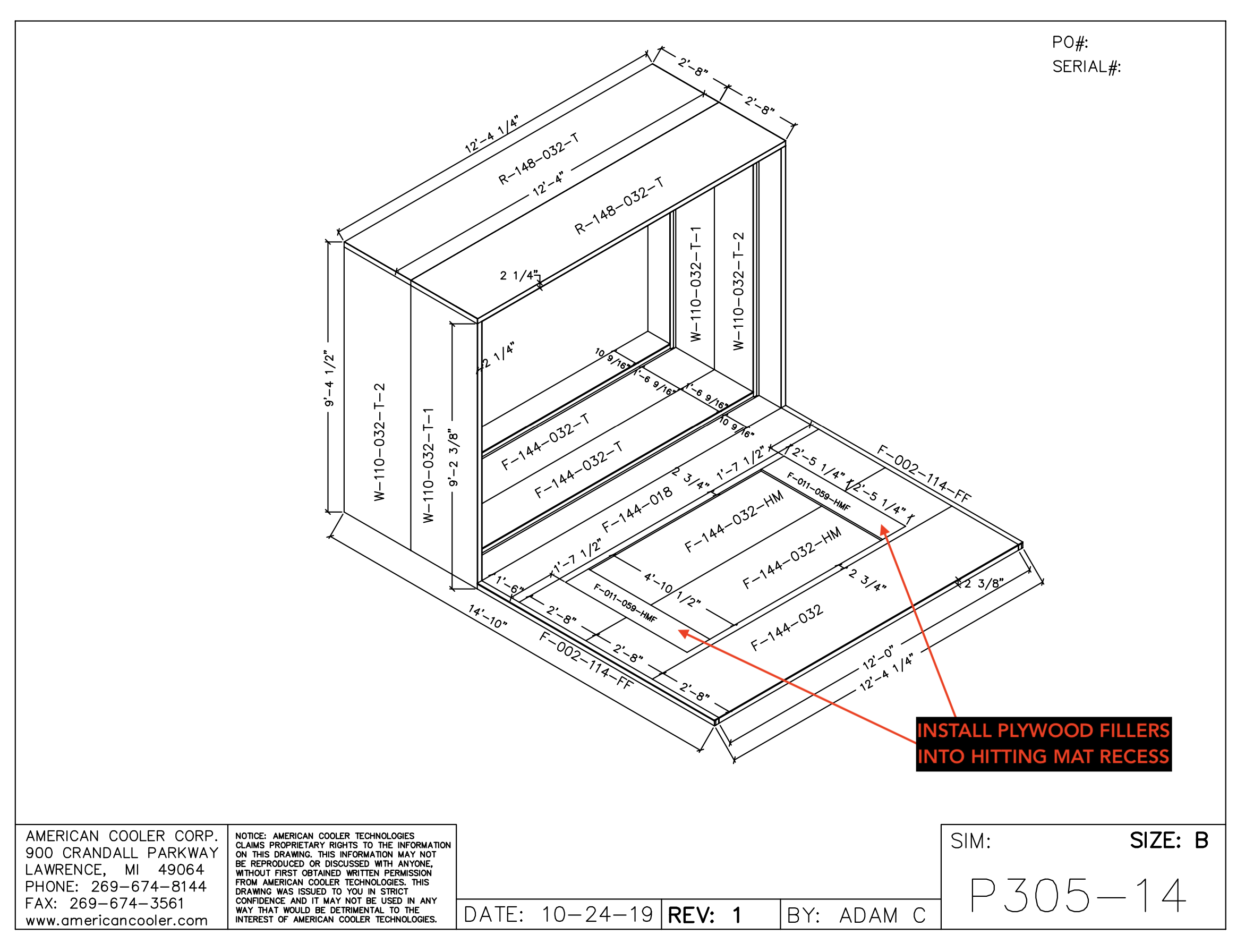

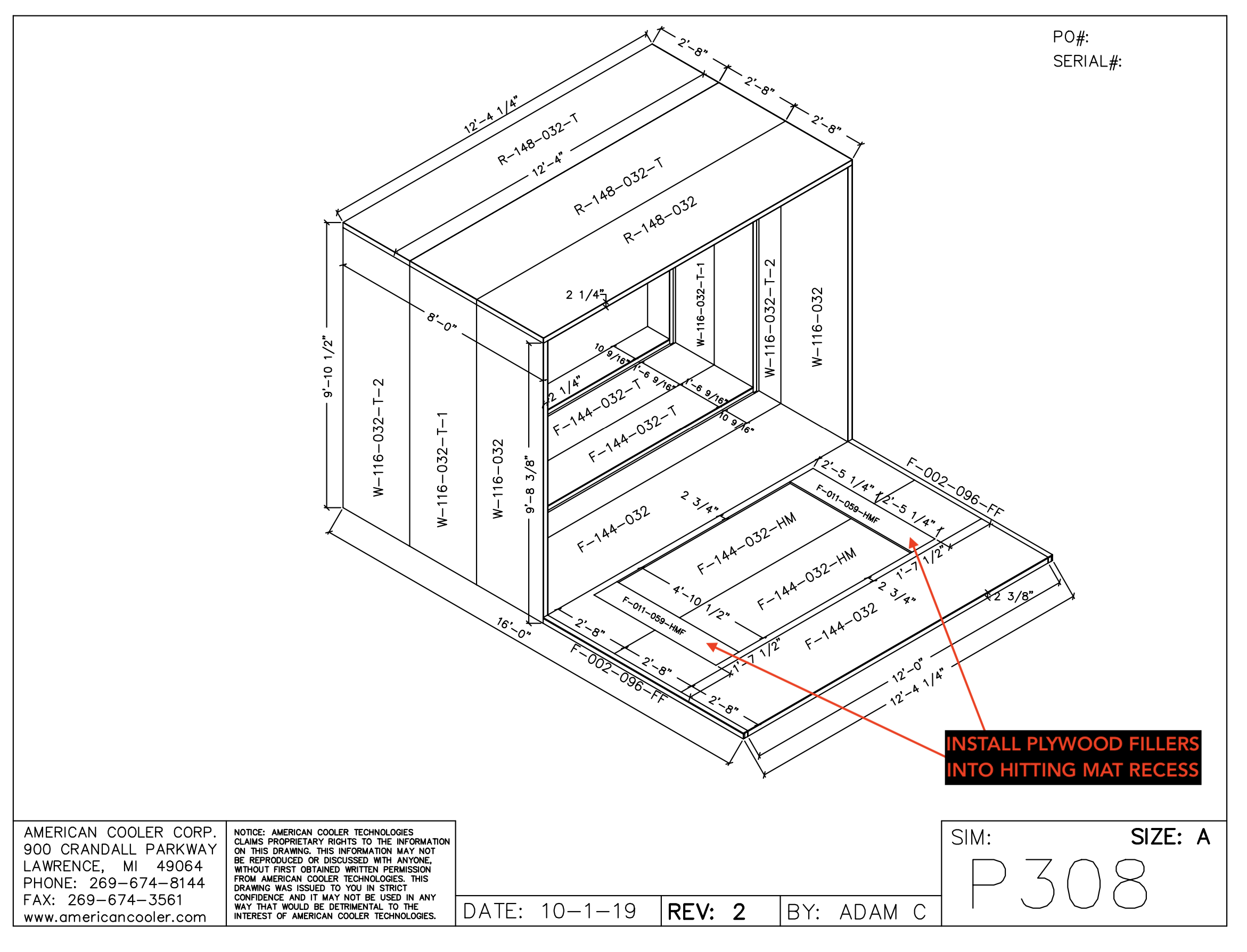

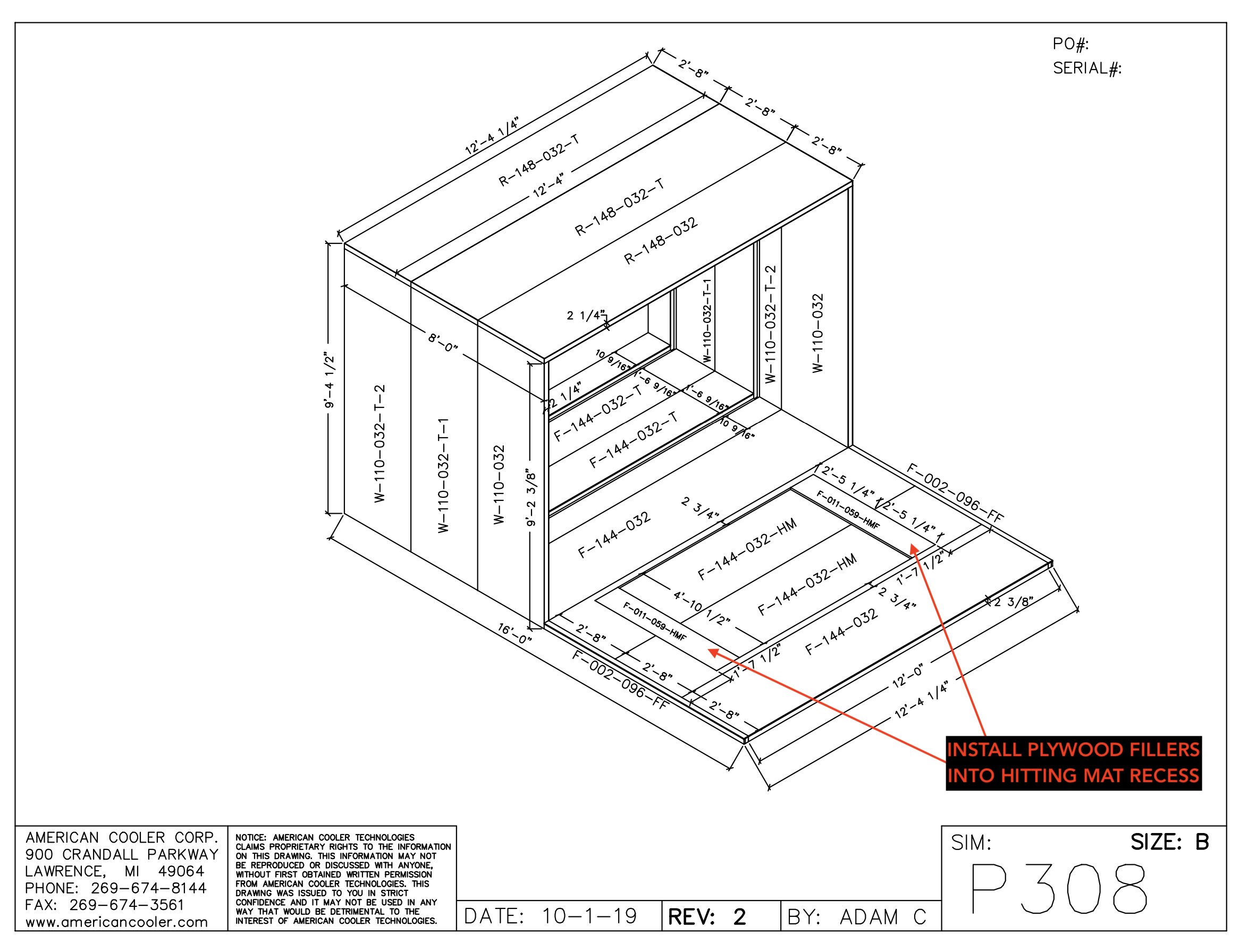

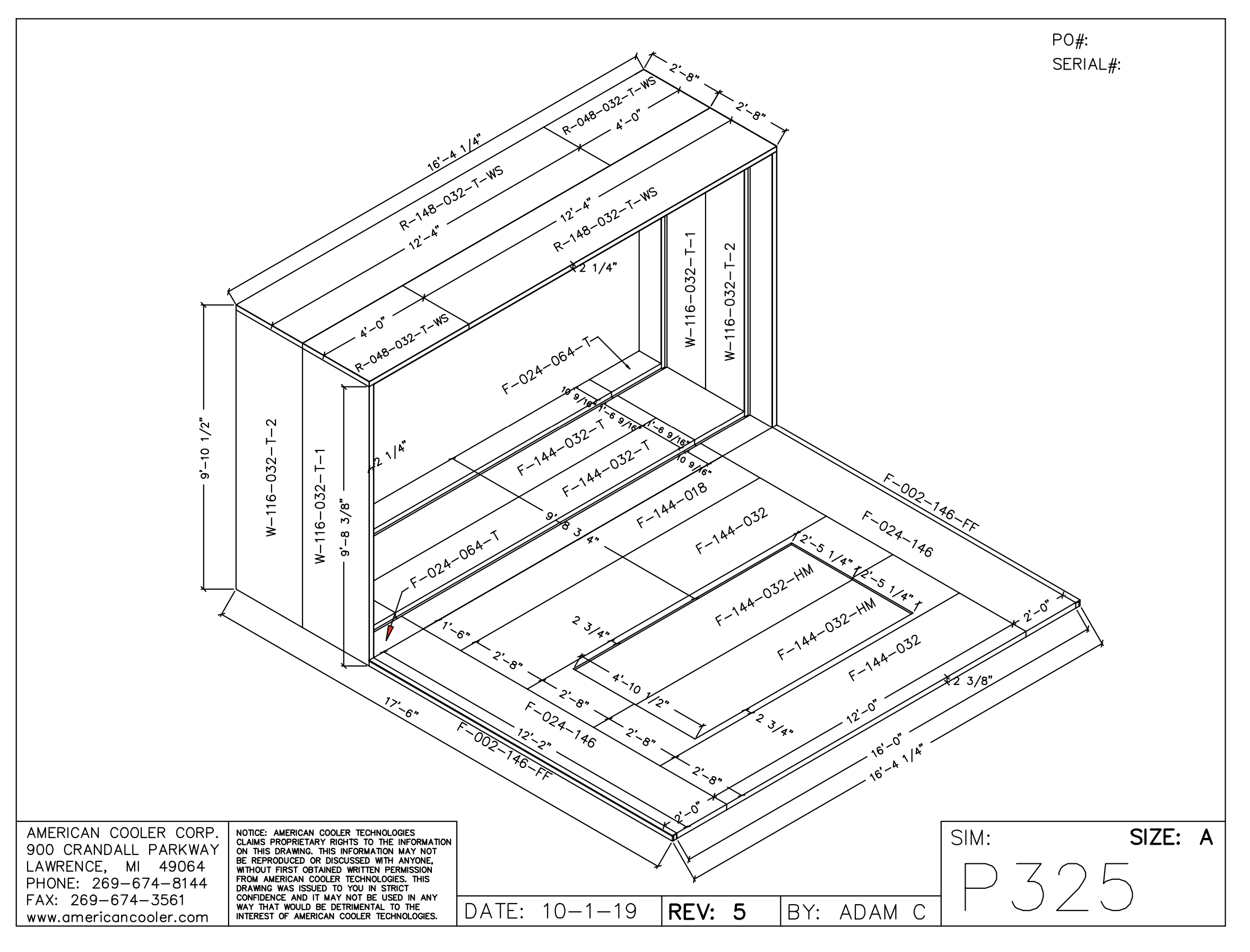

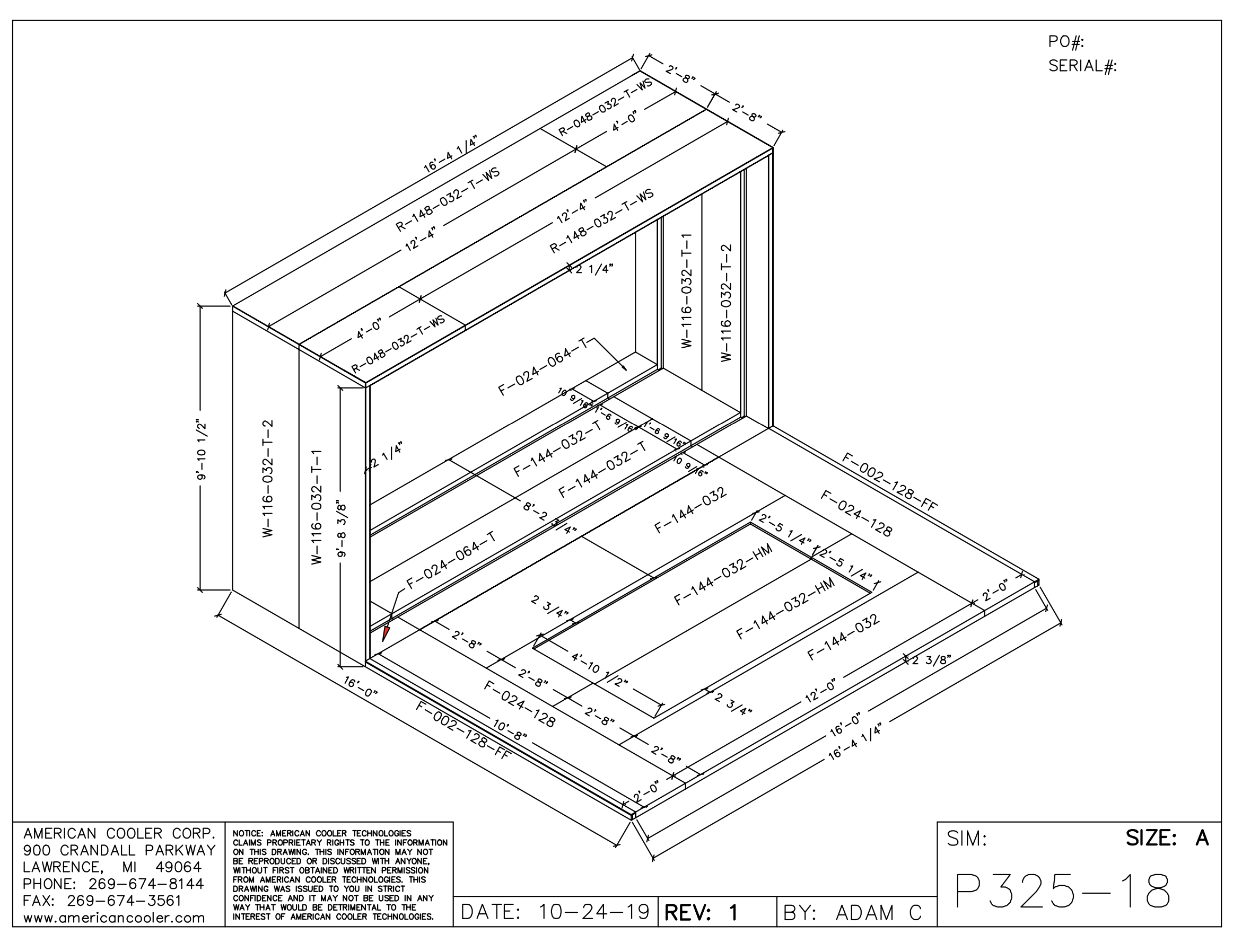

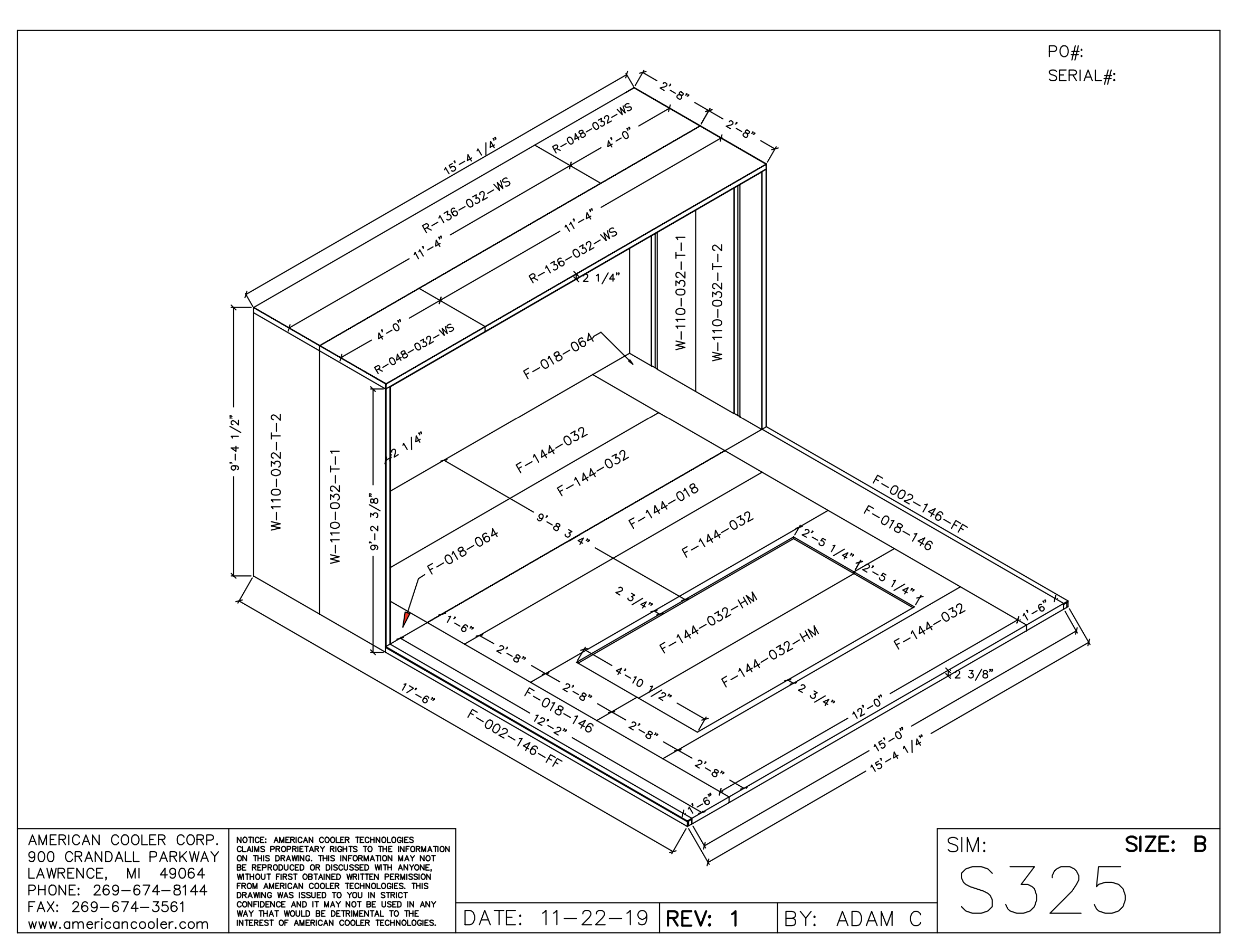

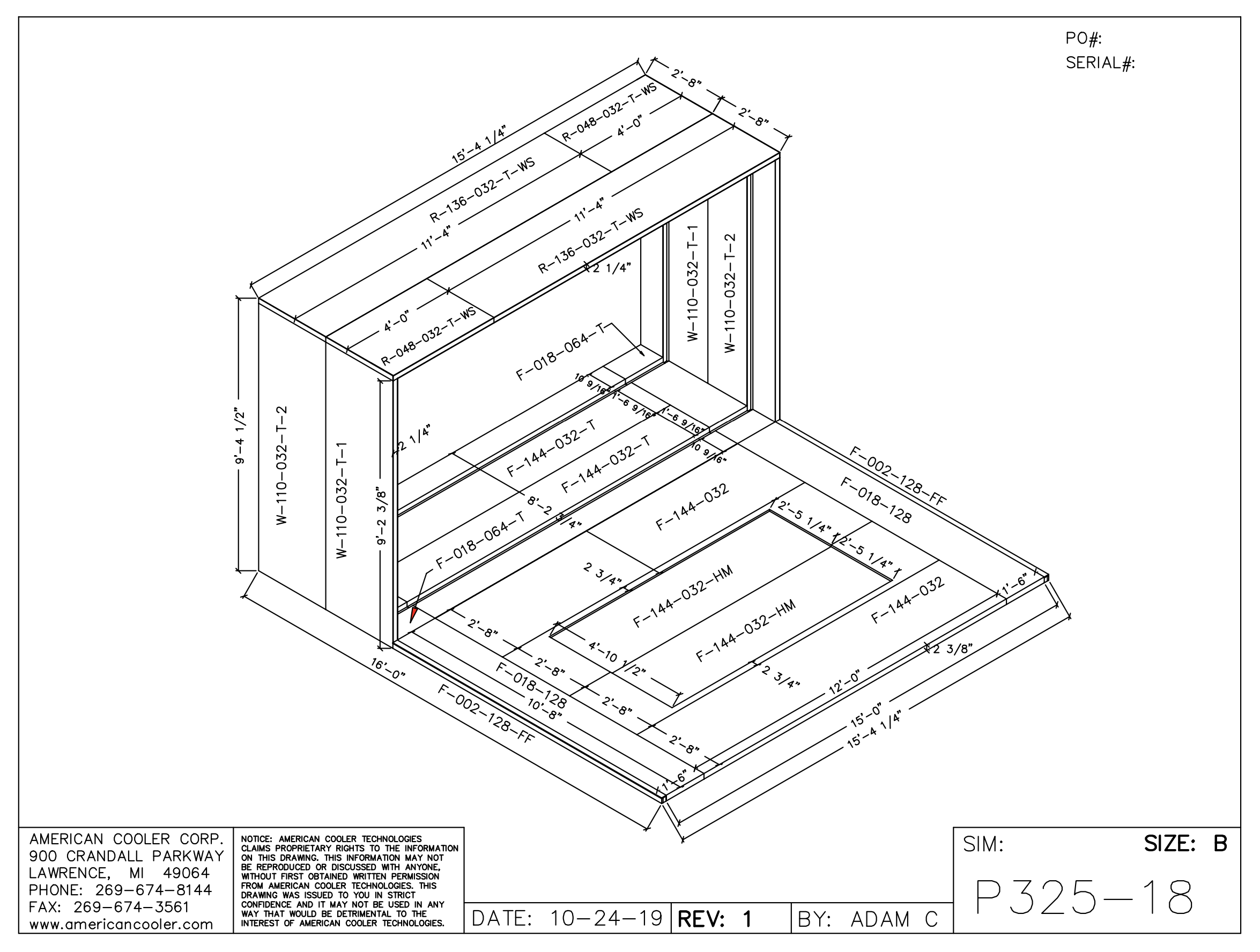

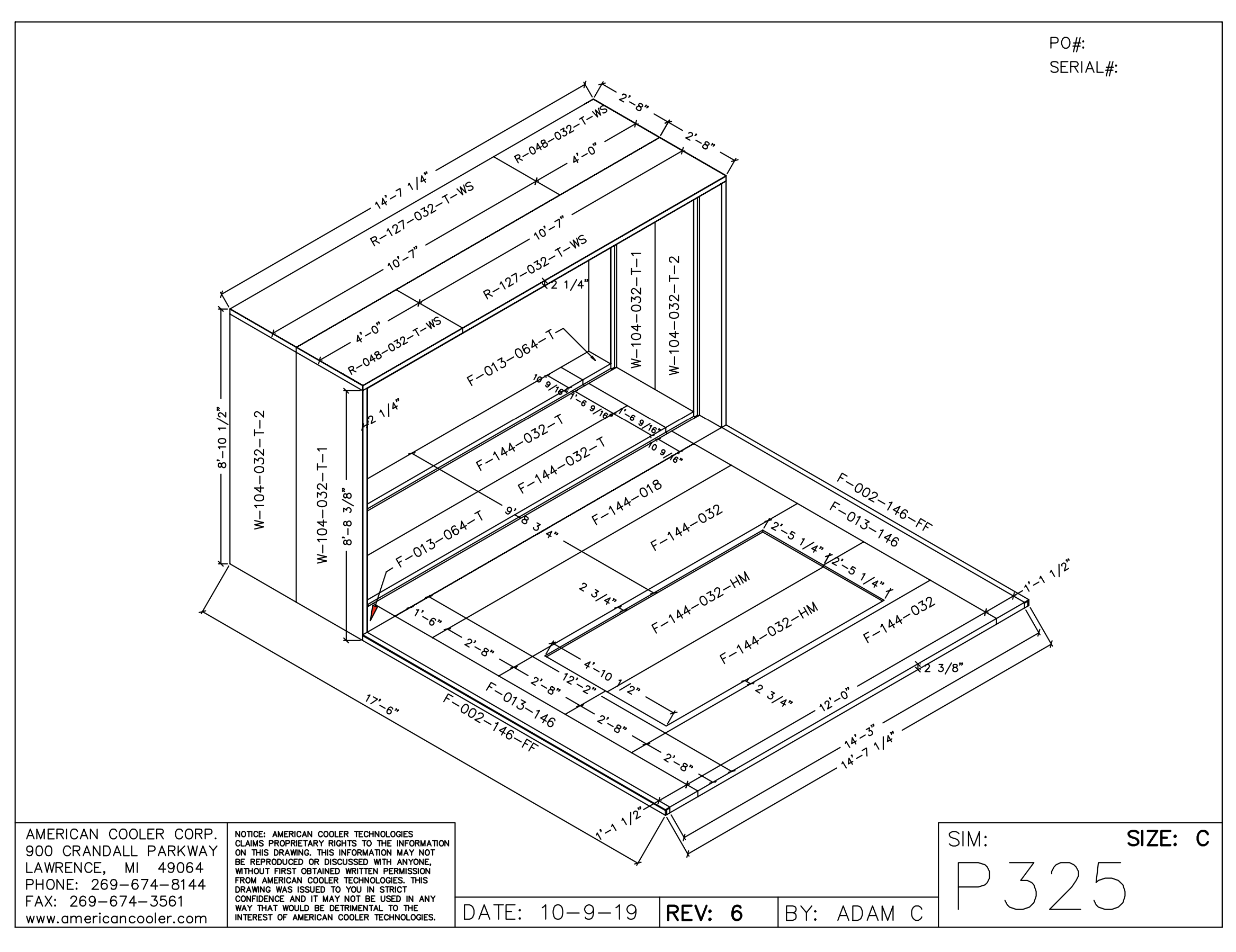

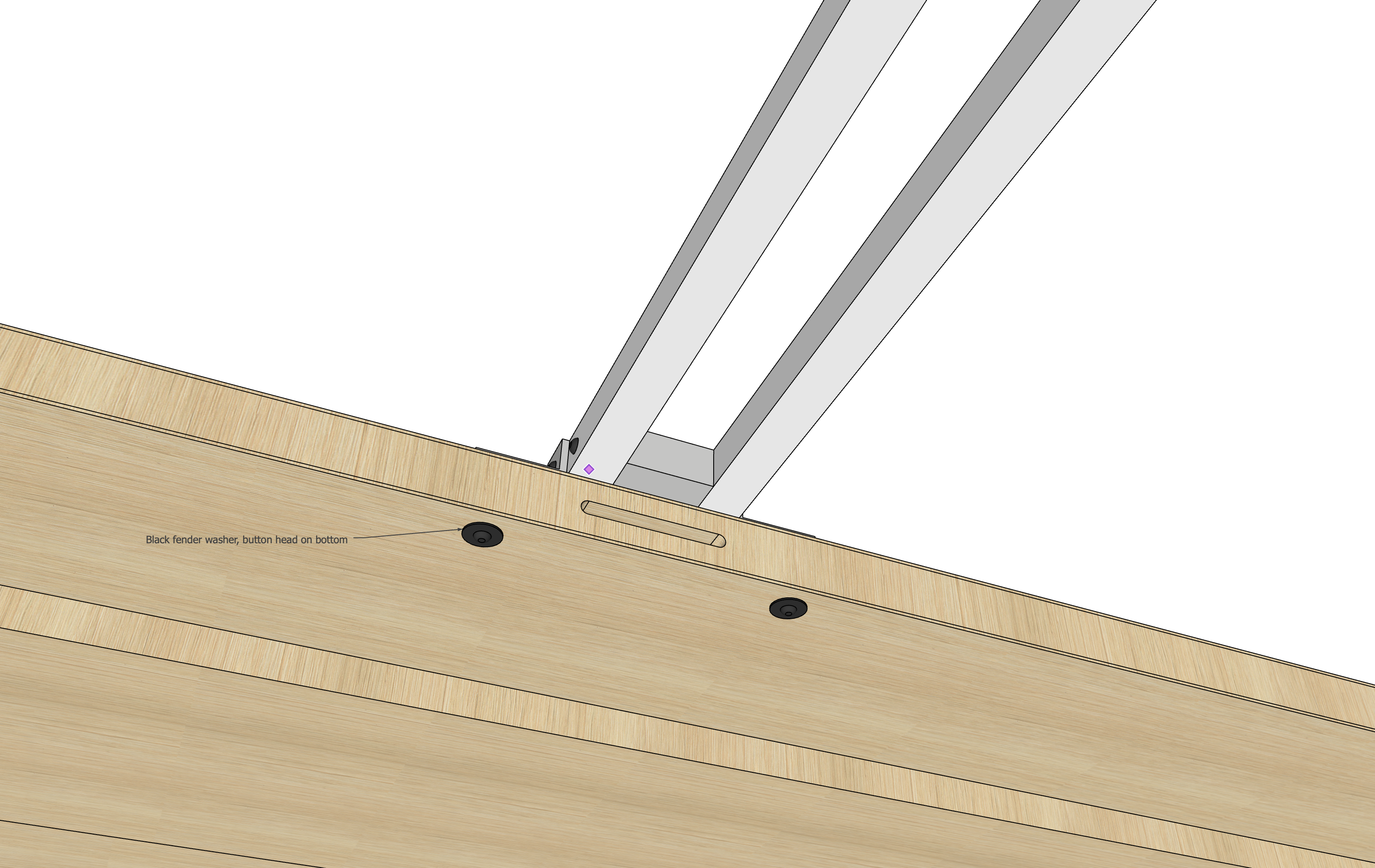

See below for an illustration of an assembled arm bar. Take note of the dimensions for correct placement of the ION3 mounting bars.

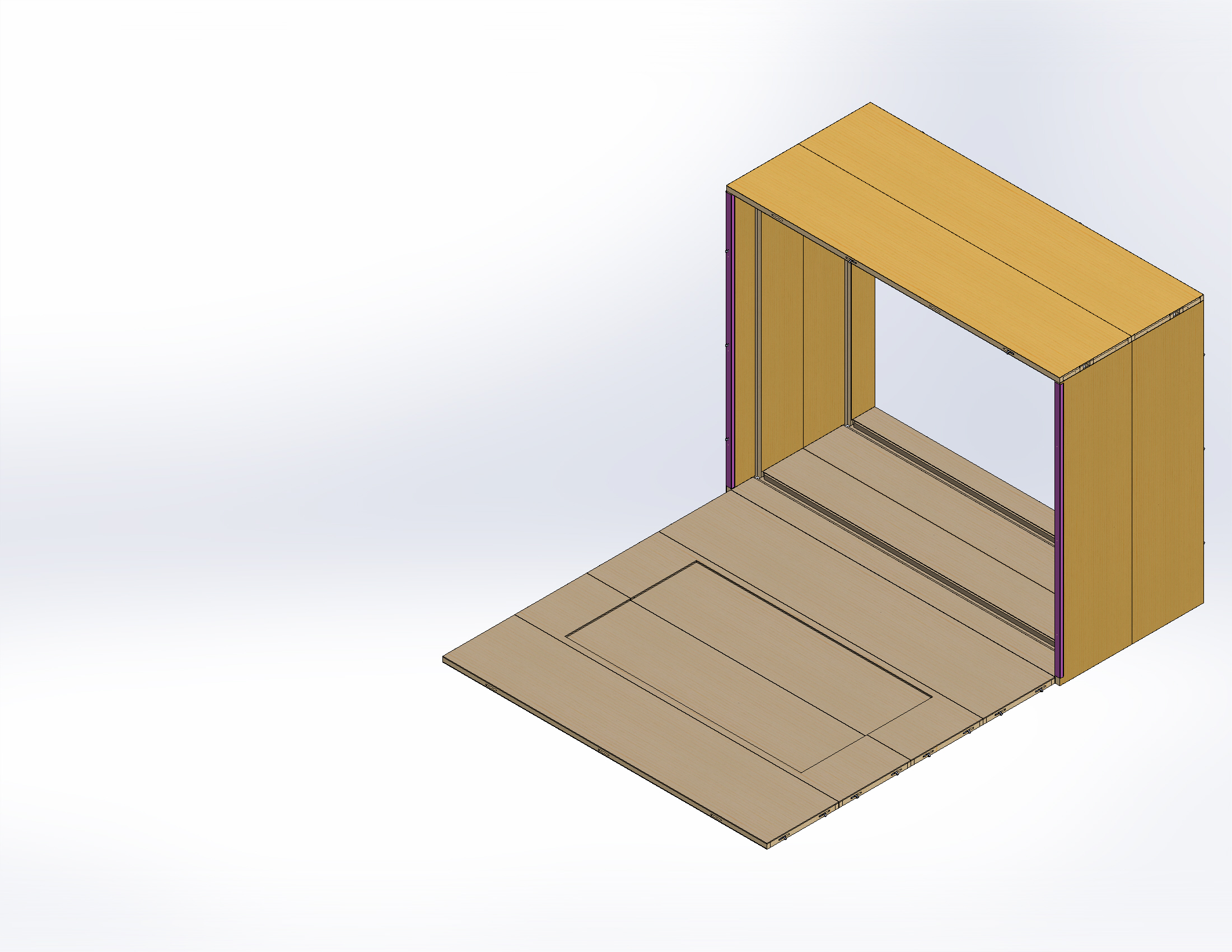

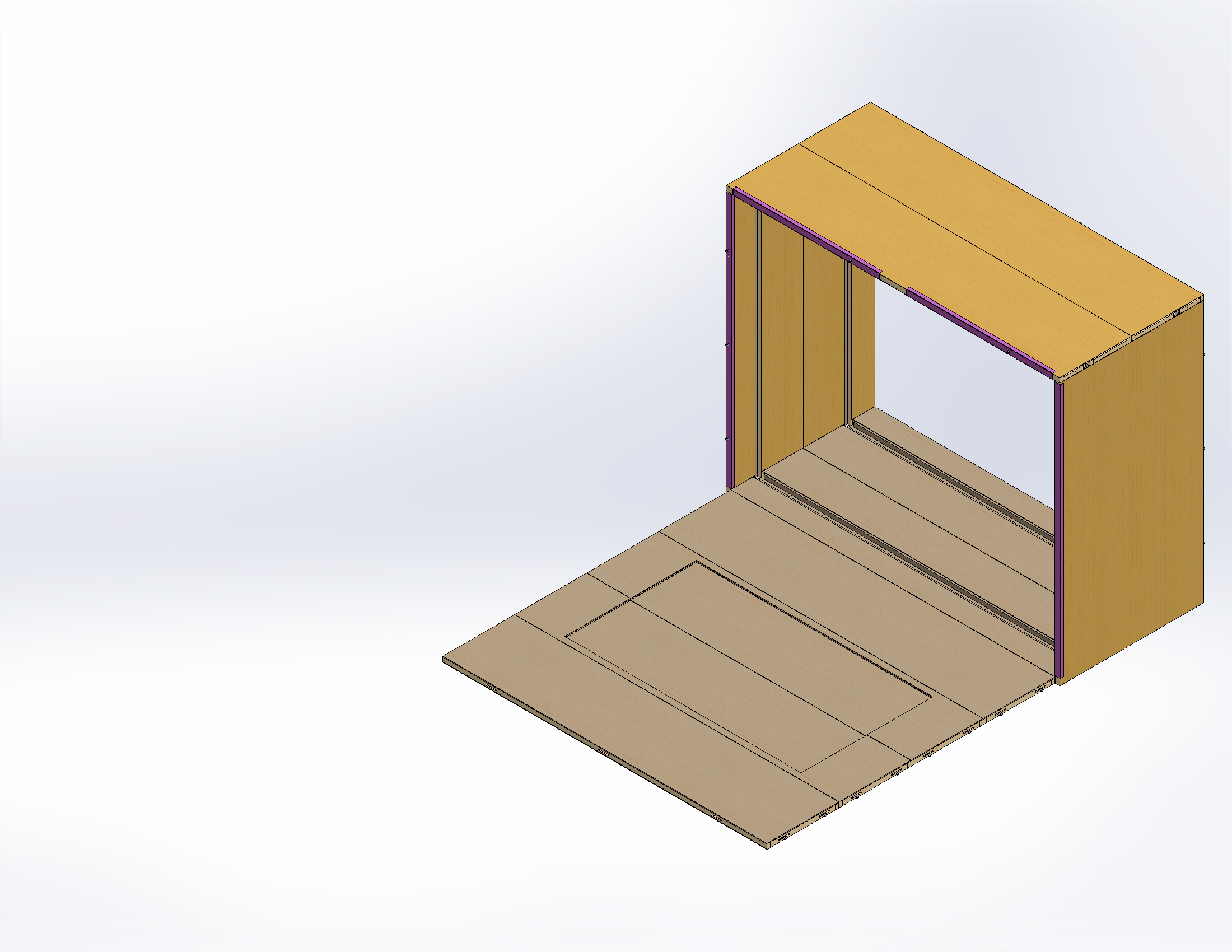

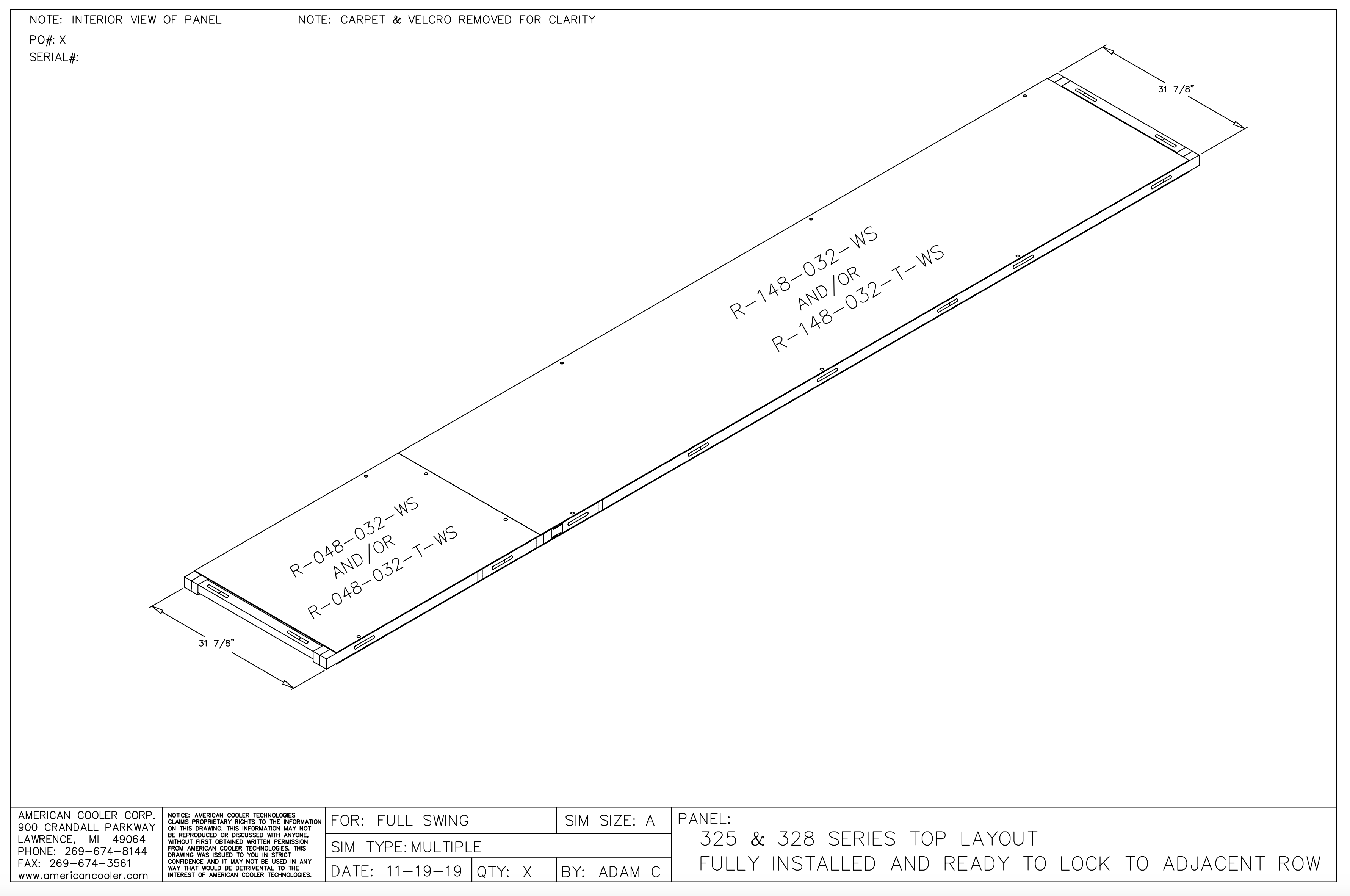

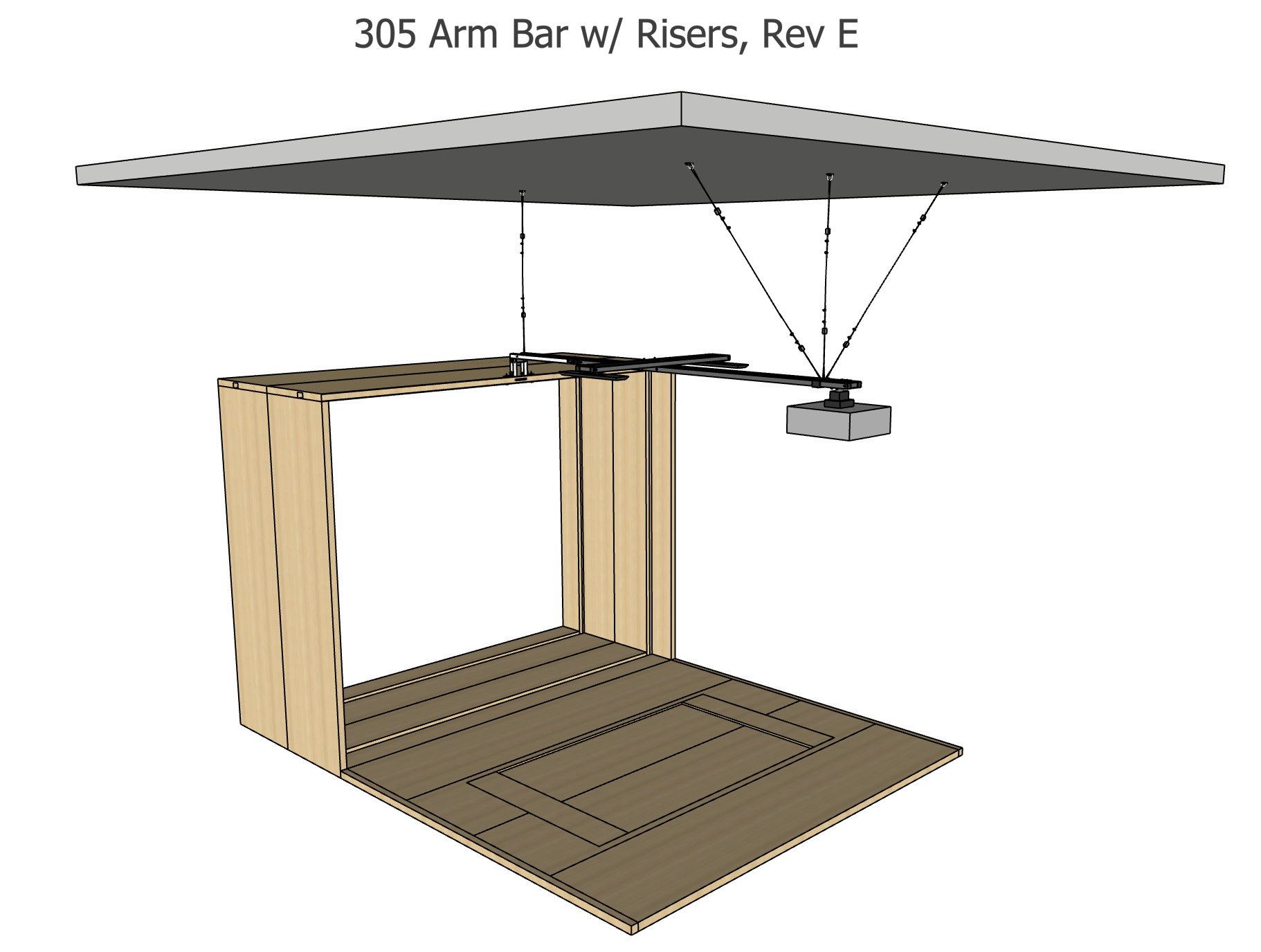

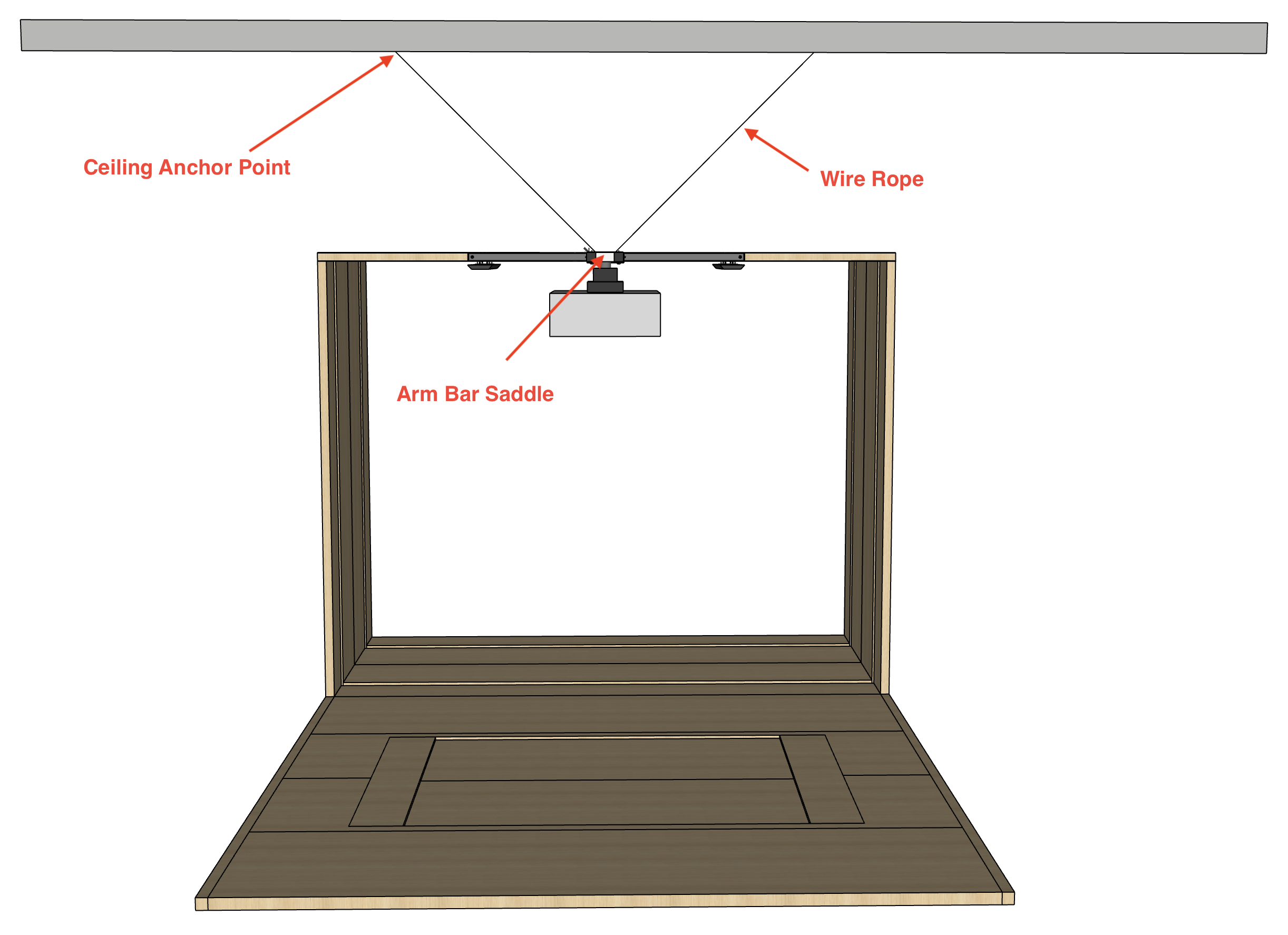

Below is an image of a complete arm bar installation with 4 safety cables in place.

Arm Bar Mounting Instructions

PARTS USED

Ceiling Attachment:

(1) Arm Bar Saddle

(4) D-Ring Anchors

(8) 1/4″ x 2″ Construction Lag Screws (for wood ceilings)

(8) 1/4″ x 1.75″ Tapcon Screws (for concrete ceilings)

(4) 20′ Wire Rope

(8) Kwik-Loc wire rope locks

(16) Wire rope clamps

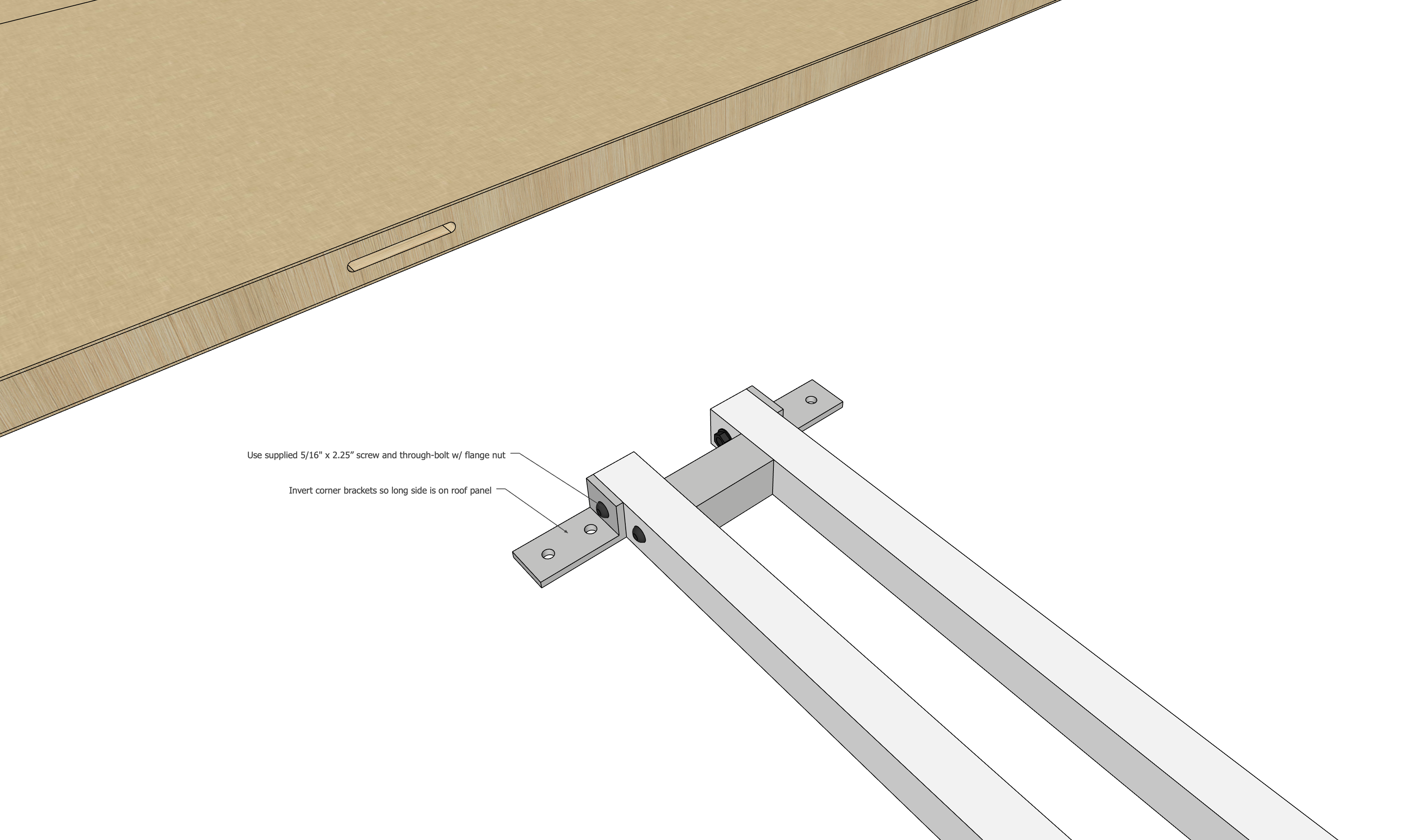

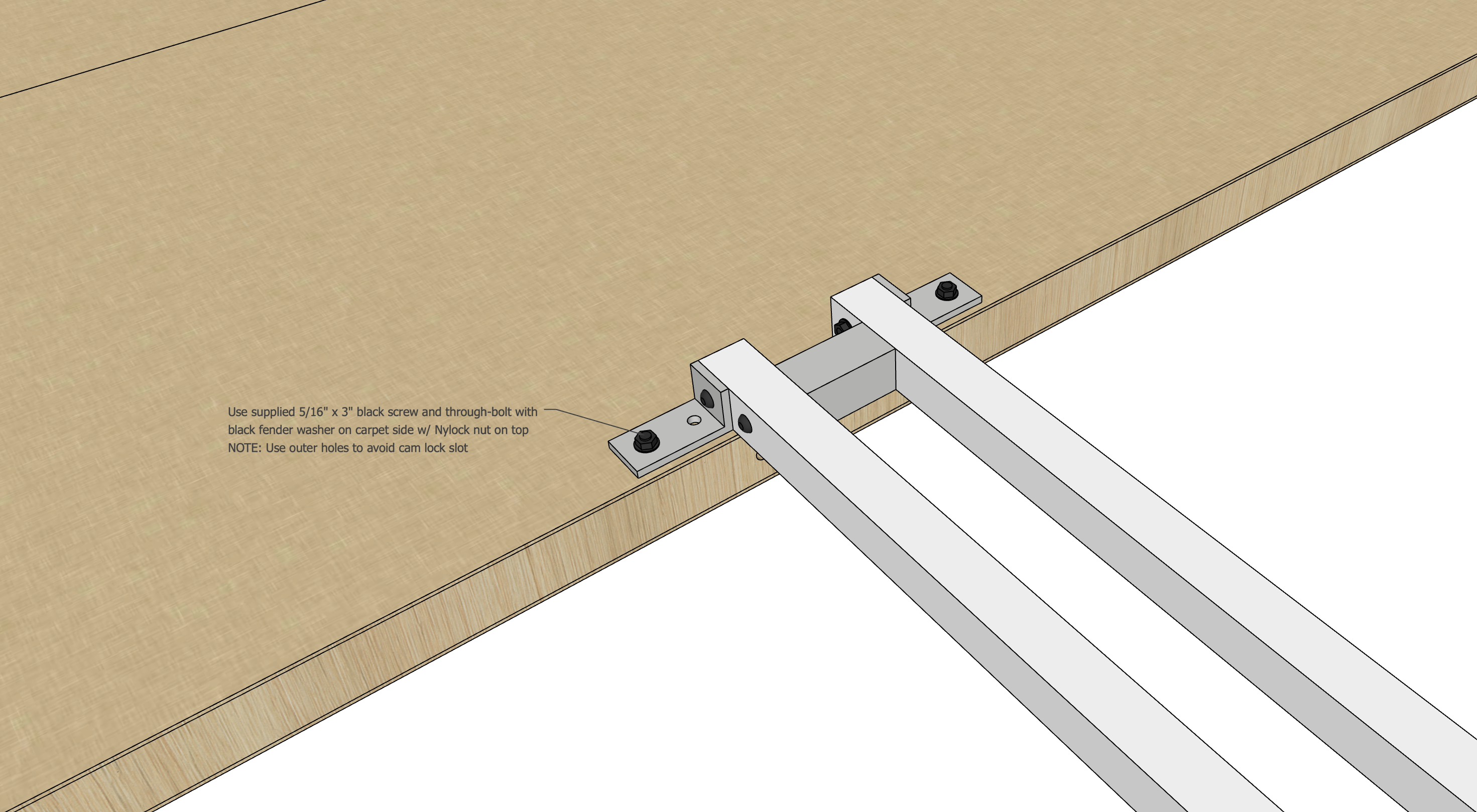

Booth Attachment:

Fully Assembled Arm Bar

(2) 5/16″ x 3″ Button Head Socket Cap Screws (Black)

(2) 5/16″ x 1.25″ Fender Washers (Black)

(2) 5/16″ Nylock Nuts (Black)

Tools:

Impact Gun

Hammer Drill (for concrete)

3/16″ Hex bit

3/8″ deep socket (supplied)

1/4″ ratchet or drill adapter

11/32″ Drill Bit (supplied)

Wrench

Vise Grips or Channel Locks

Arm Bar Cables

Directions:

IMPORTANT: If you are retrofitting safety cables onto an armbar, remove projector from Arm Bar before attempting the retrofit.

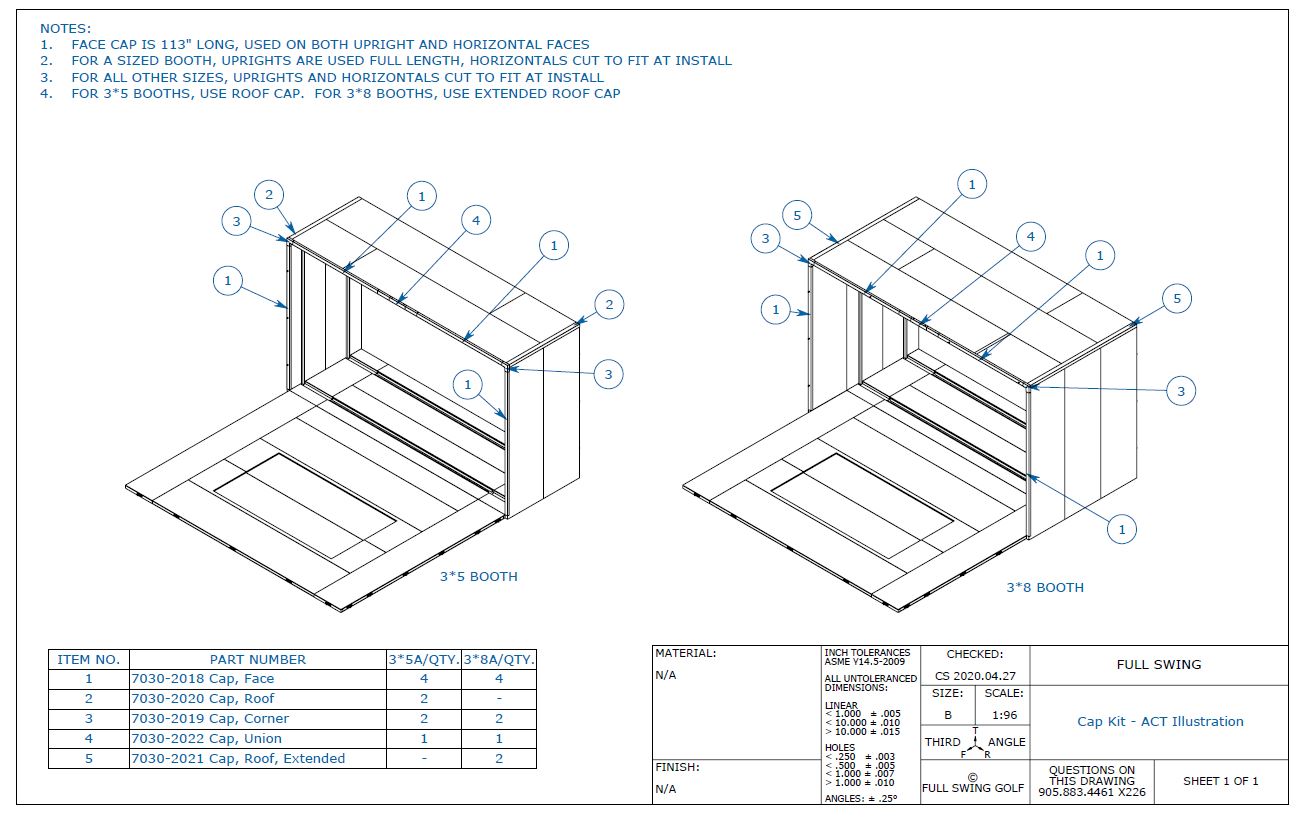

A finished Arm Bar installation will have four safety cables installed. One at the simulator end going straight up, one at the projector end going straight up, and two in a V from the projector end. Below are notes on installing the two V cables from the projector end.

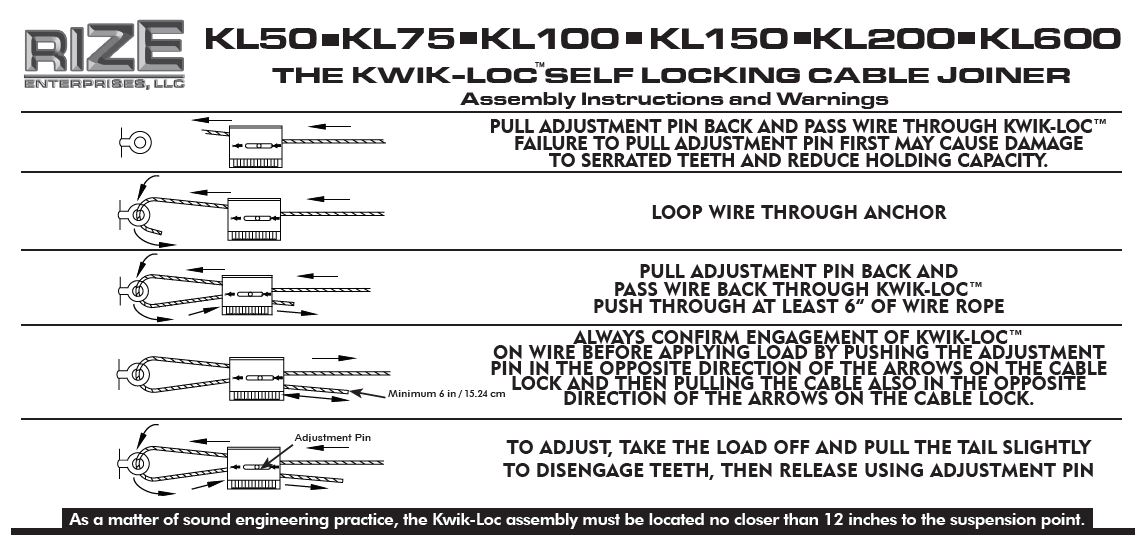

1. Ensure all cables and Kwik-Loc devices are properly installed.

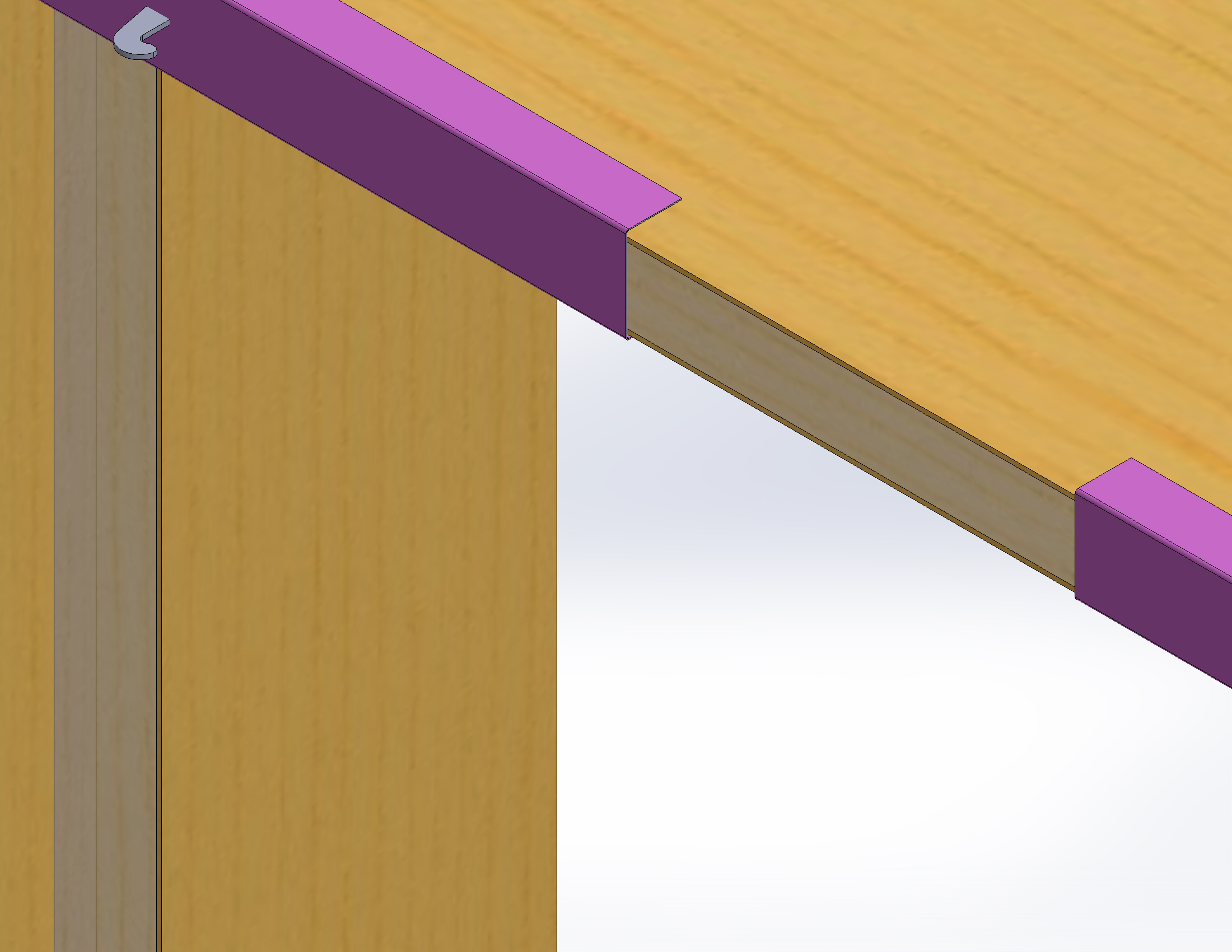

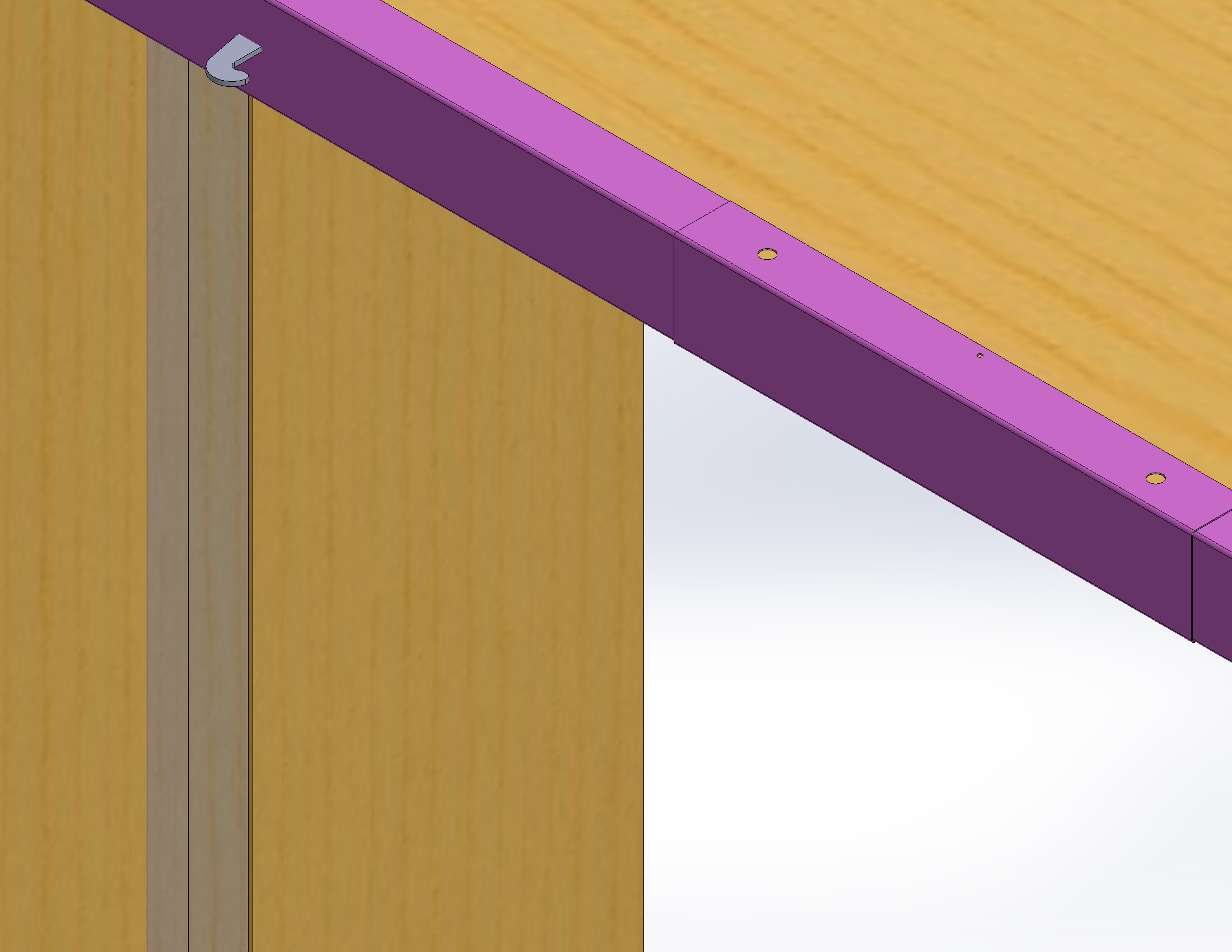

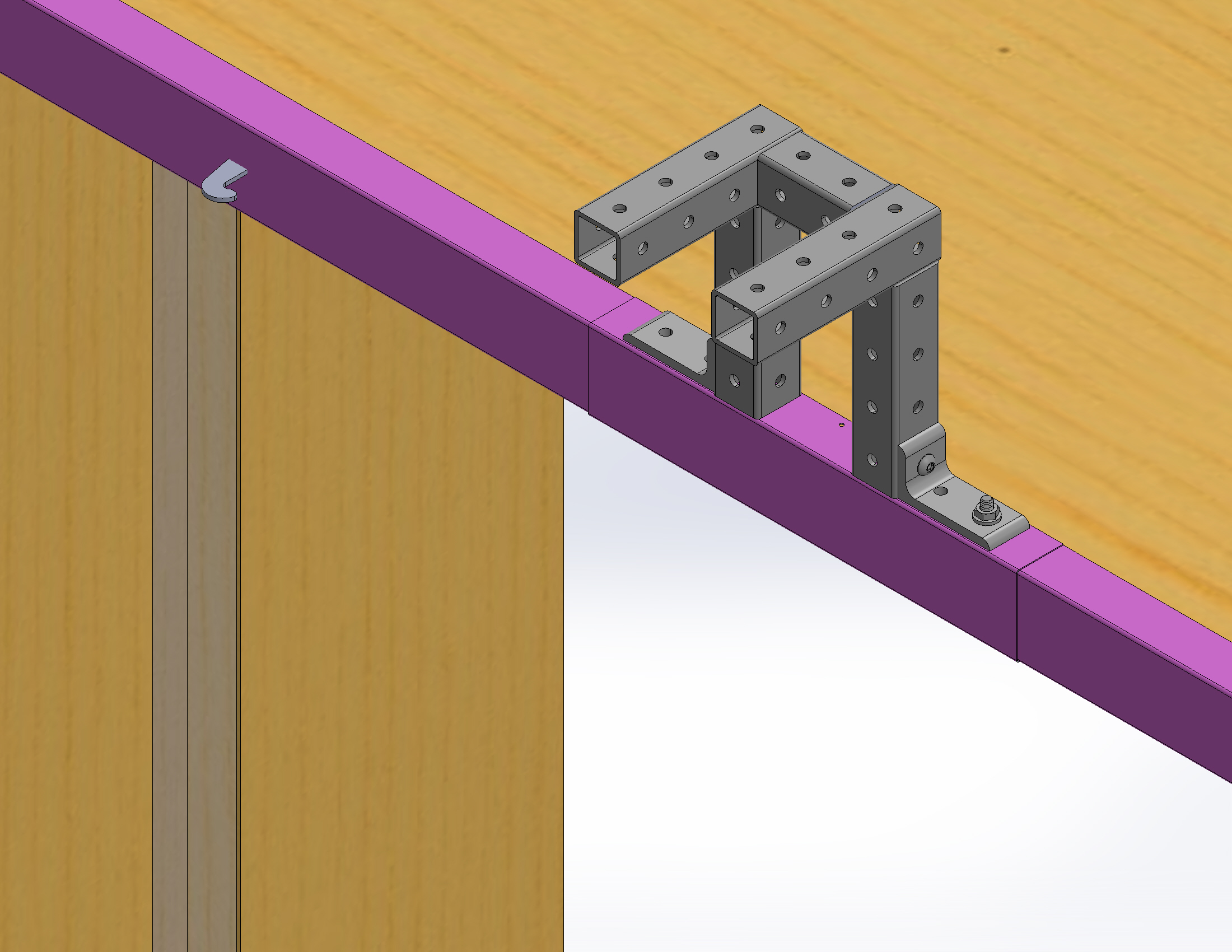

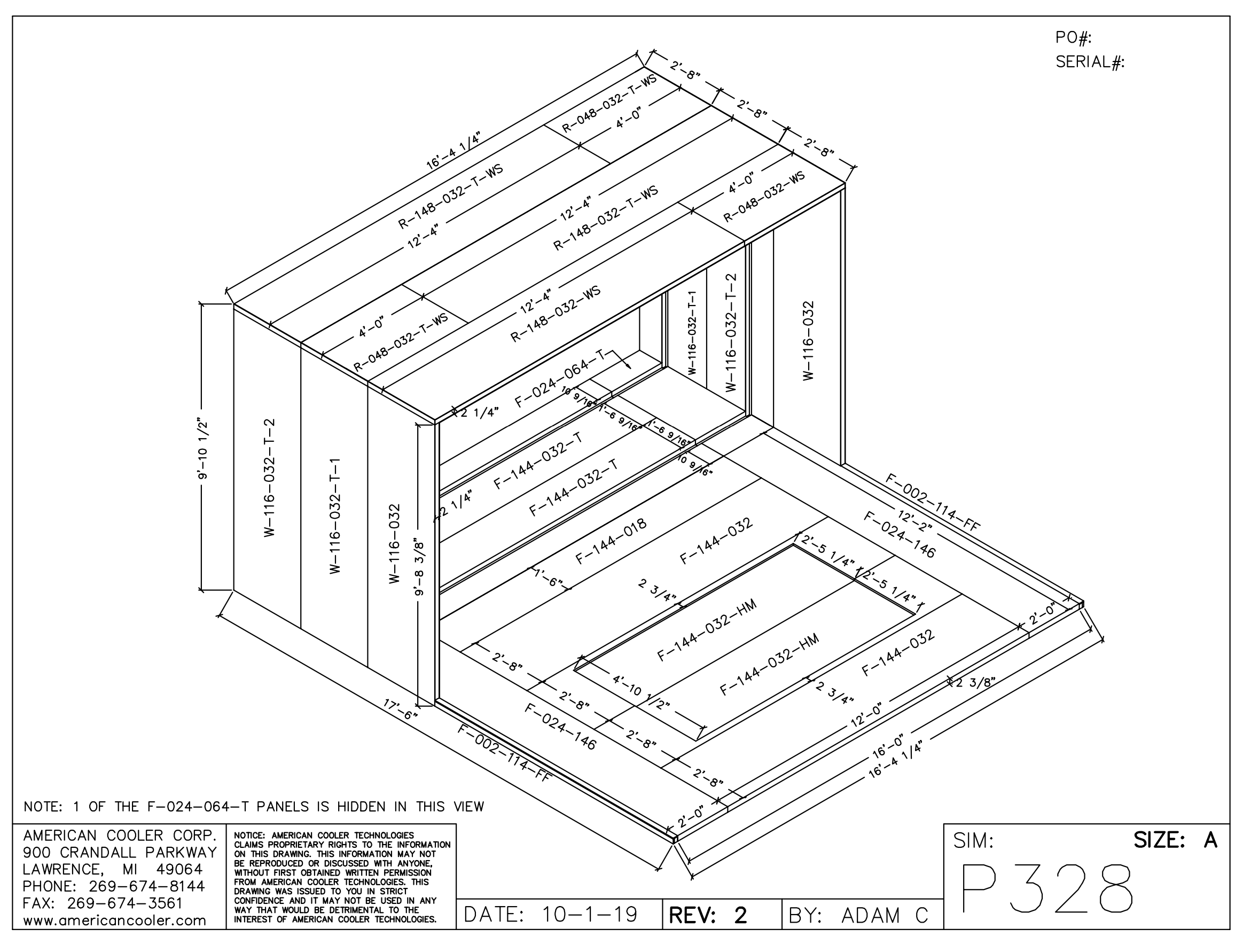

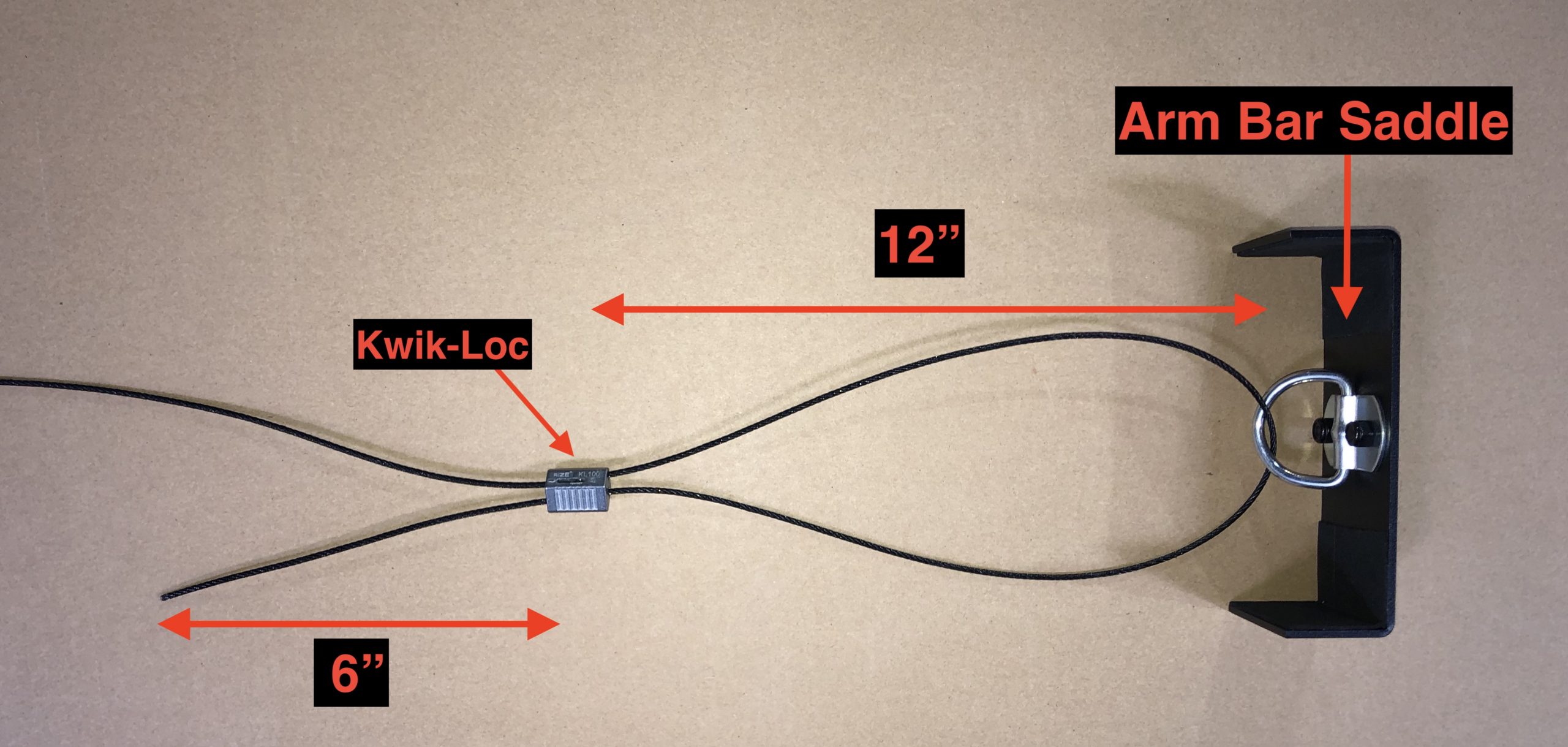

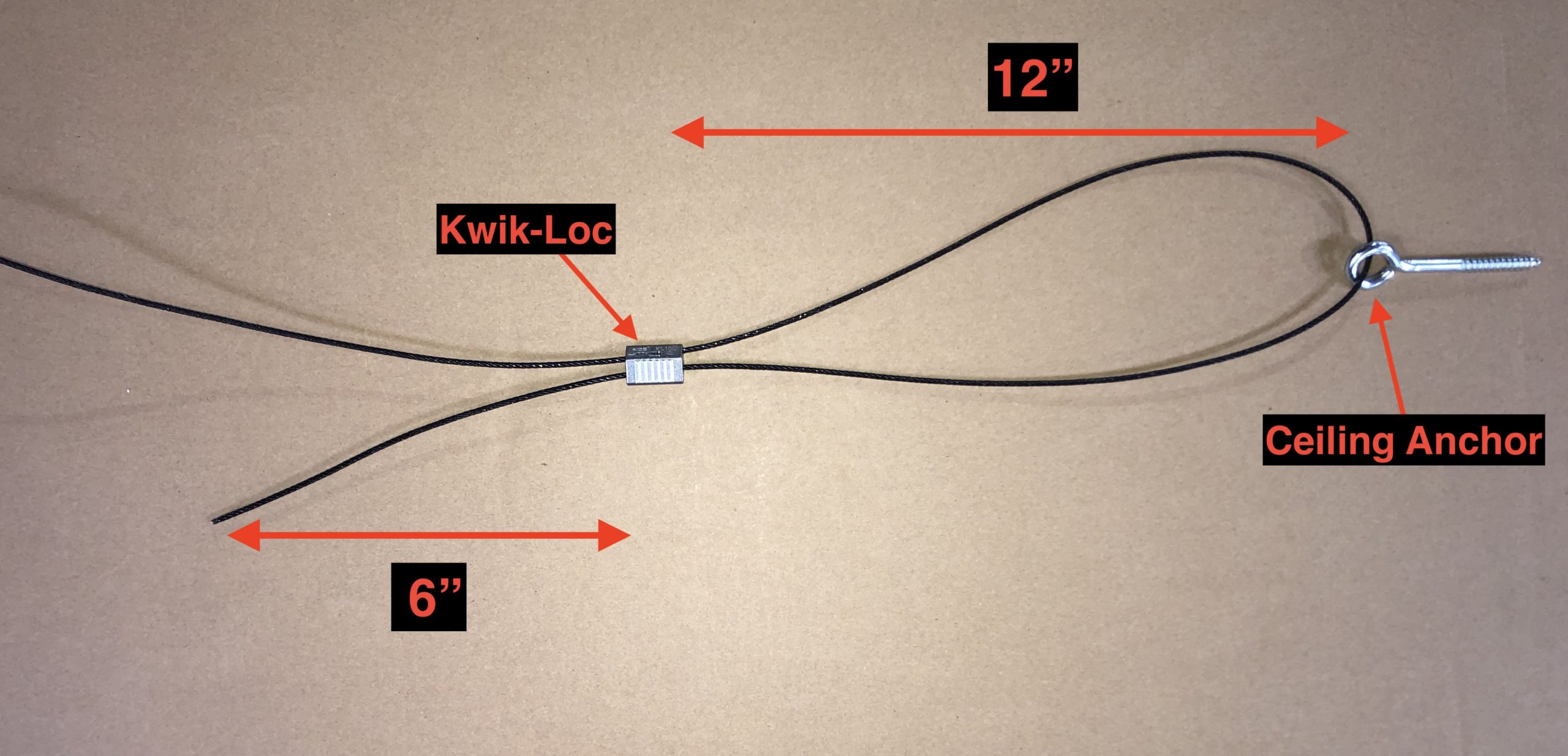

1A) Each Arm Bar should have two independent cables in a 45 degree “V” pattern. Each cable should be attached to an anchor point on the ceiling and attached to the Arm Bar Saddle as shown below.

1B) Each Kwik-Loc device should be 12” away from any anchor points or saddle and have at least a 6” tail coming out the back of the Kwik-Loc.

Please refer to Kwik-Loc’s instructions for proper installation and engagement of the Kwik-Loc device (attached at end of document).

NOTE: If cables are not properly installed and cannot be corrected onsite, please contact Full Swing for further direction.

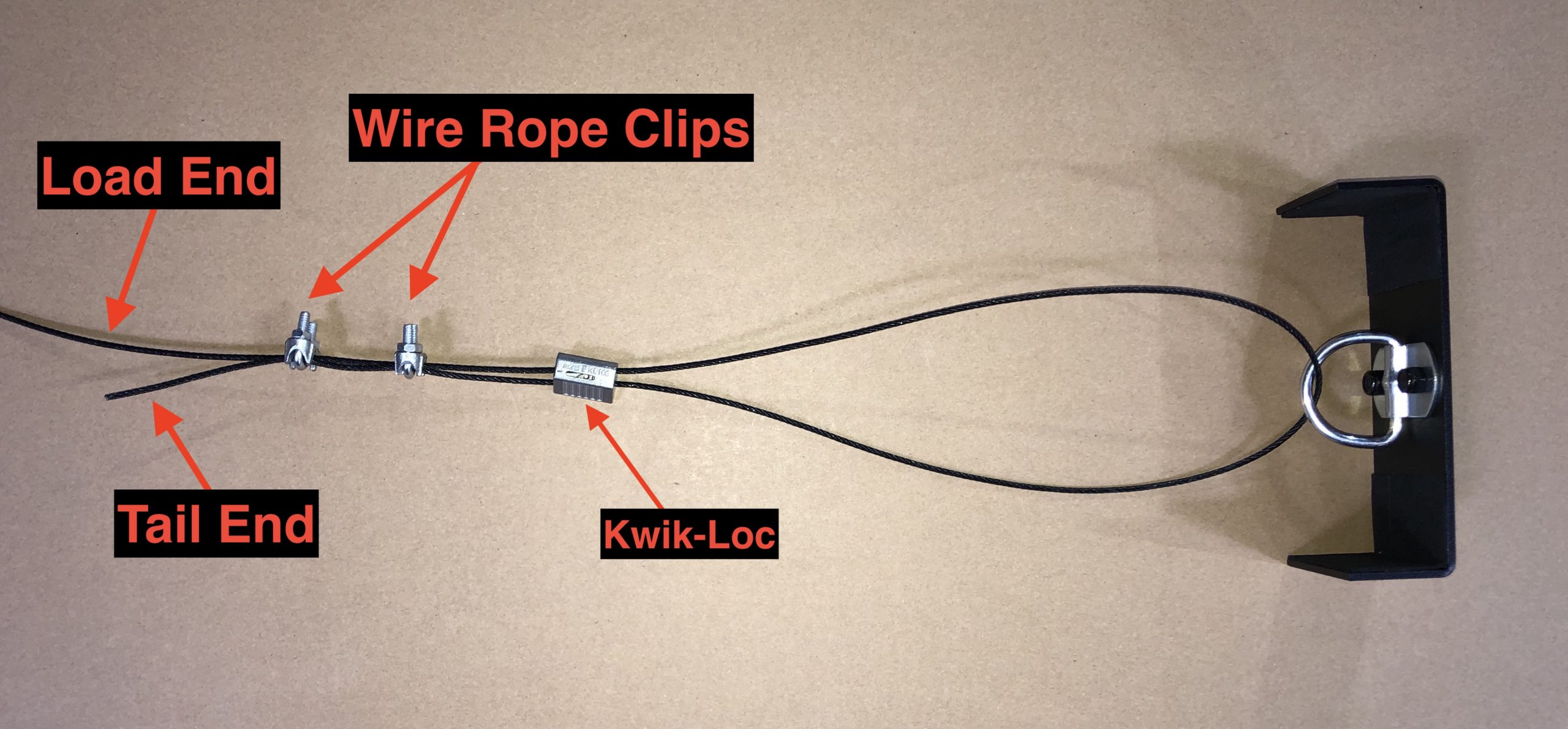

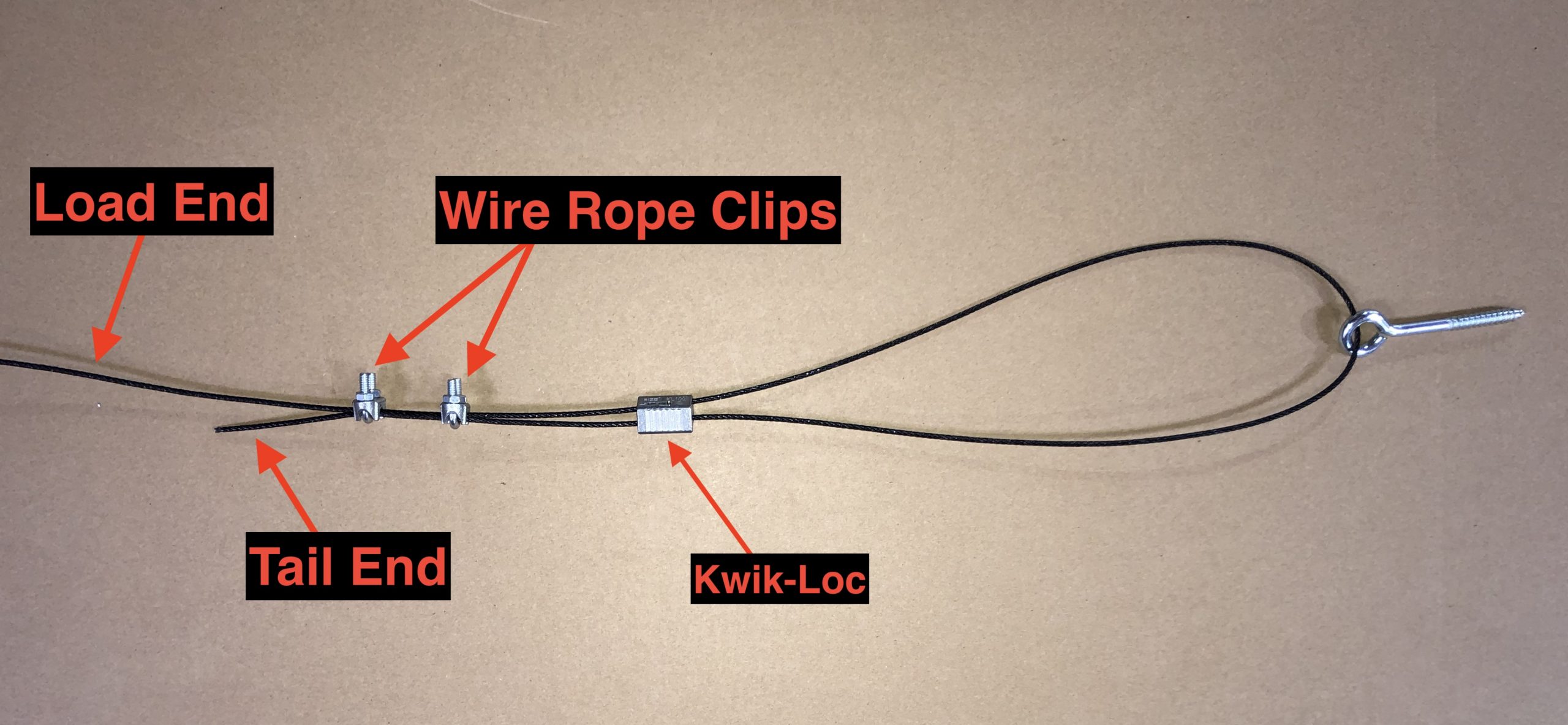

2) Install two wire rope clips on tail end of each Kwik-Loc device.

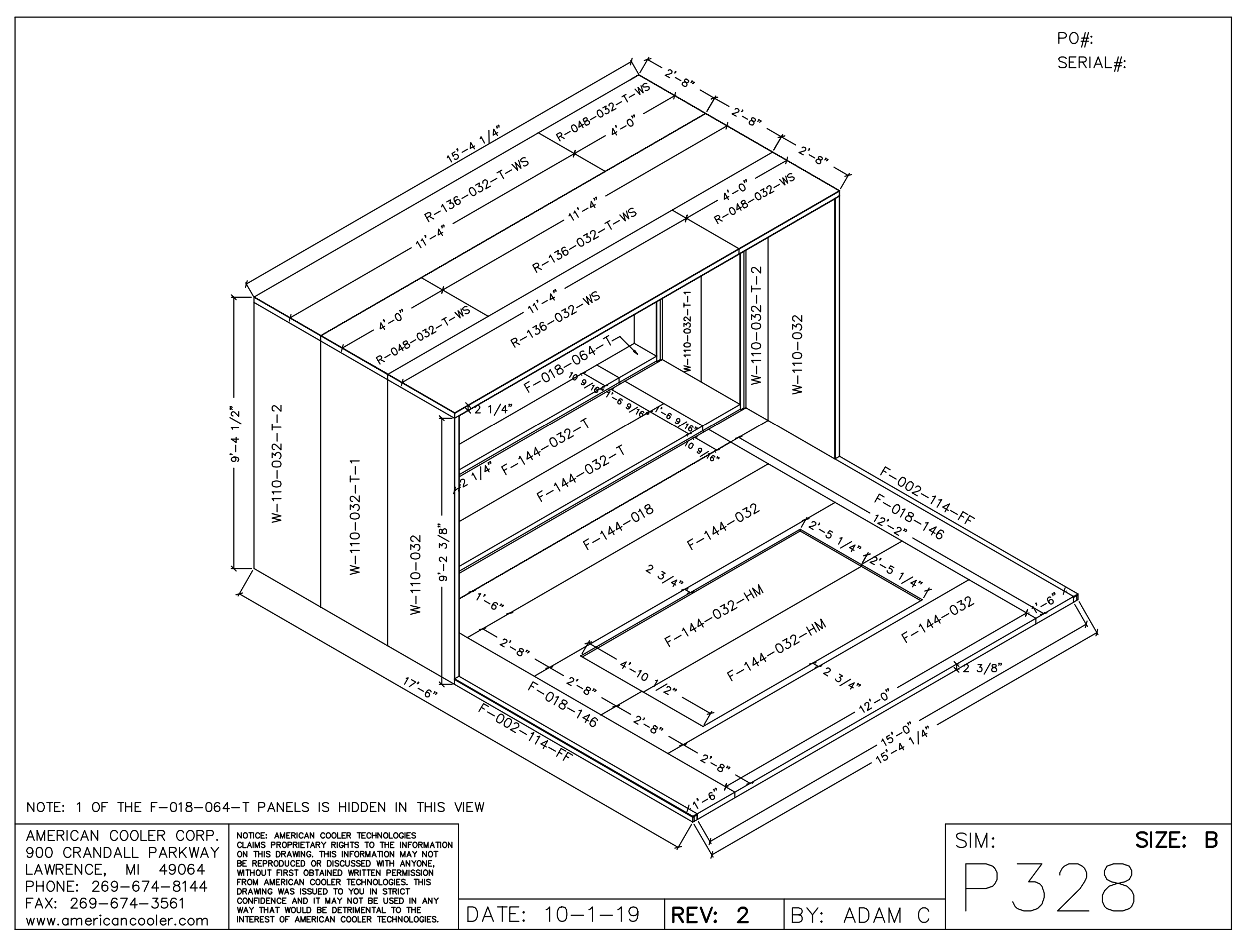

2A) Space the wire rope clips about 3” apart and install clips so that the base is on the long (live) end and the U-bolt is on the short (tail) end as shown below.

Every safety cable end should have this same configuration – 2 wire rope clips and a Kwik-Loc device. So with a total of 4 cables with 2 ends each, you will repeat this configuration 8 times.

2B) Use Vise-Grips or pliers to hold the rope clip and tighten the nuts on the wire rope clip with the 3/8” socket. The nuts should be tight enough to keep the cable from slipping but please be careful to avoid damaging the cable.